Category

Product Description

The crusher impact plate's manufacturing process directly impacts its service life and crushing efficiency. Typically made of high manganese steel, high chromium cast iron or composite wear-resistant materials to withstand high-strength impact and wear, the production involves:

✅1) Precision casting (with controlled cooling to avoid internal stress) for dense, defect-free structures;

✅2) Heat treatment (e.g., quenching and tempering) to optimize hardness-impact resistance balance;

✅3) Optional surface treatment (surfacing wear-resistant layers or ceramic spraying) for improved wear resistance;

✅4) CNC fine machining to ensure installation hole and contact surface accuracy, enabling seamless coordination with the rotor system.

The entire process chain needs to strictly control the quality of each link to produce impact plate components that are both durable and efficient and stable. This systematic manufacturing process ensures that the impact plate can still maintain excellent performance under harsh working conditions.

Casting process: lost foam casting

Applicable machines: crusher

Applicable industries: mining, coal, steel, cement plants, etc.

Material types: high manganese steel、high chromium cast iron

Chemical composition % of high manganese steel

Chemical composition % of high chromium cast iron

This product is a customized product and is produced according to customer drawings or samples.

Casting Process

Casting Process

Casting Process

Casting Process

Casting Process

Delivery site

Delivery site

Delivery site

Delivery site

Delivery site

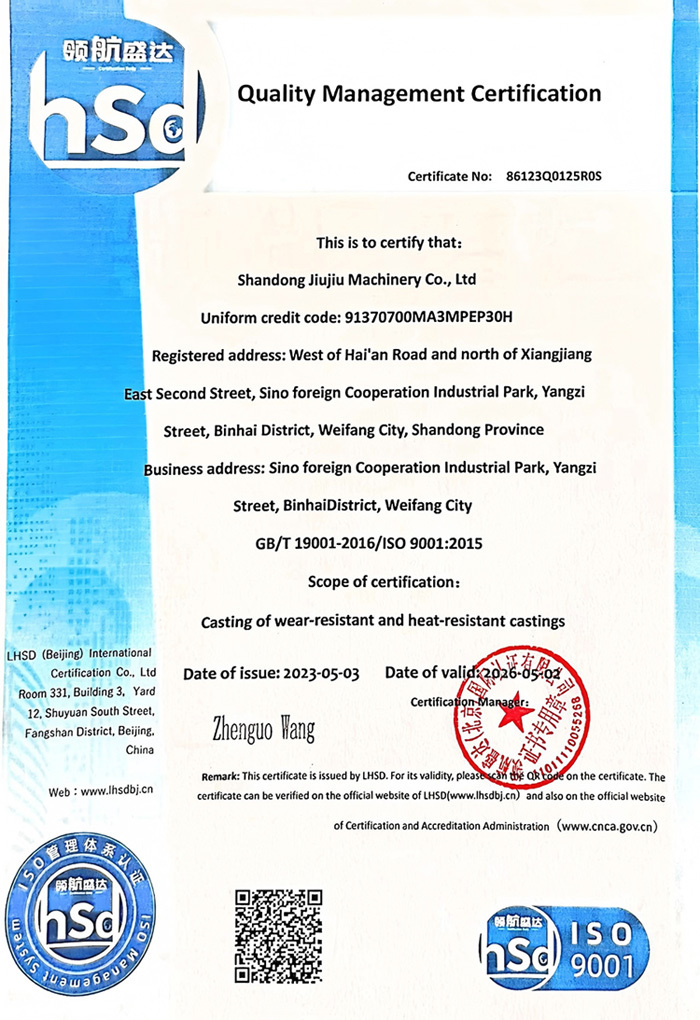

Inspections & Certifications

Certifications

Certifications

Customer visits

Customer visits

Customer visits

Customer visits

Customer visits

Keywords

crusher impact plates

crusher impact plates

Contact Us

Telephone:+86-13792621099

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products