Category

Product Description

Heat resistant steel is an alloy engineered for high-temperature environments (usually above 500°C), with properties of oxidation resistance, corrosion resistance, and creep resistance, finding wide use across industries. Heat-resistant steels for Waste-to-Energy (WTE) applications typically include stainless steels, chrome moly steels.

Its unique performance stems from special alloy compositions (chromium, nickel, tungsten, etc.) and refined smelting. These elements boost high-temperature resistance, stabilize its structure to avoid grain growth, and form a dense oxide film that slows oxidation, extending service life.

Casting process: sand casting

Applicable machines: furnaces, incinerators, Industrial furnaces and incinerators, etc.

Applicable industries: energy, petrochemical, cement, and furnace/foundry operations, etc.

Material types: heat resistant steel

Chemical composition % of heat resistant steel

This product is a customized product and is produced according to customer drawings or samples.

Casting Process

Casting Process

Casting Process

Casting Process

Casting Process

Delivery site

Delivery site

Delivery site

Delivery site

Delivery site

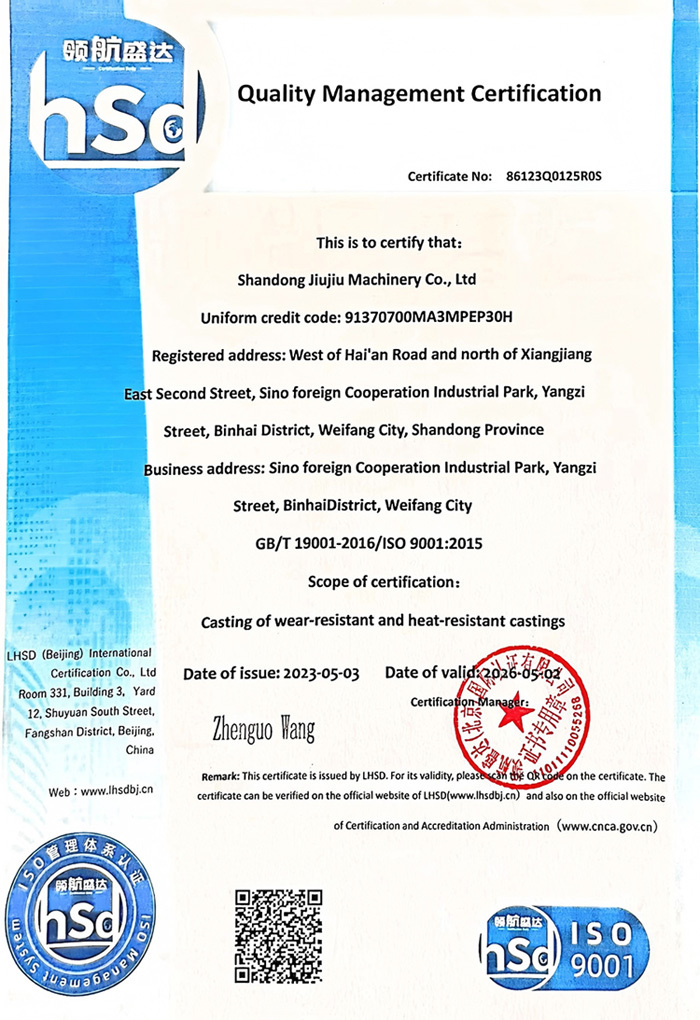

Inspections & Certifications

Certifications

Certifications

Customer visits

Customer visits

Customer visits

Customer visits

Customer visits

Keywords

heat resistaht steel for WTE

heat resistaht steel for WTE

Contact Us

Telephone:+86-13792621099

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products