Category

Product Description

The impact crusher features three core plate components—blow bars (hammers), impact plates, and side plates—with impact plates being pivotal to refining crushing results. As a key crusher wear-resistance casting and essential crusher spare part, impact plates are installed behind the rotor, forming a secondary crushing chamber with blow bars.

Typically crafted from high-manganese steel or alloy steel, they withstand repeated material impacts. Their adjustable gap with the rotor allows precise control over discharge particle size, while corrugated surfaces enhance material rebound and secondary crushing.

Working with blow bars (primary crushers) and side plates (casing protectors), impact plates ensure uniform particle distribution, boost crushing efficiency, and reduce energy consumption.

Casting process: lost foam casting

Applicable machines: crusher

Applicable industries: mining, construction, cement, etc.

Material types: high manganese steel

Chemical composition % of high manganese steel

This product is a customized product and is produced according to customer drawings or samples.

Casting Process

Casting Process

Casting Process

Casting Process

Casting Process

Delivery site

Delivery site

Delivery site

Delivery site

Delivery site

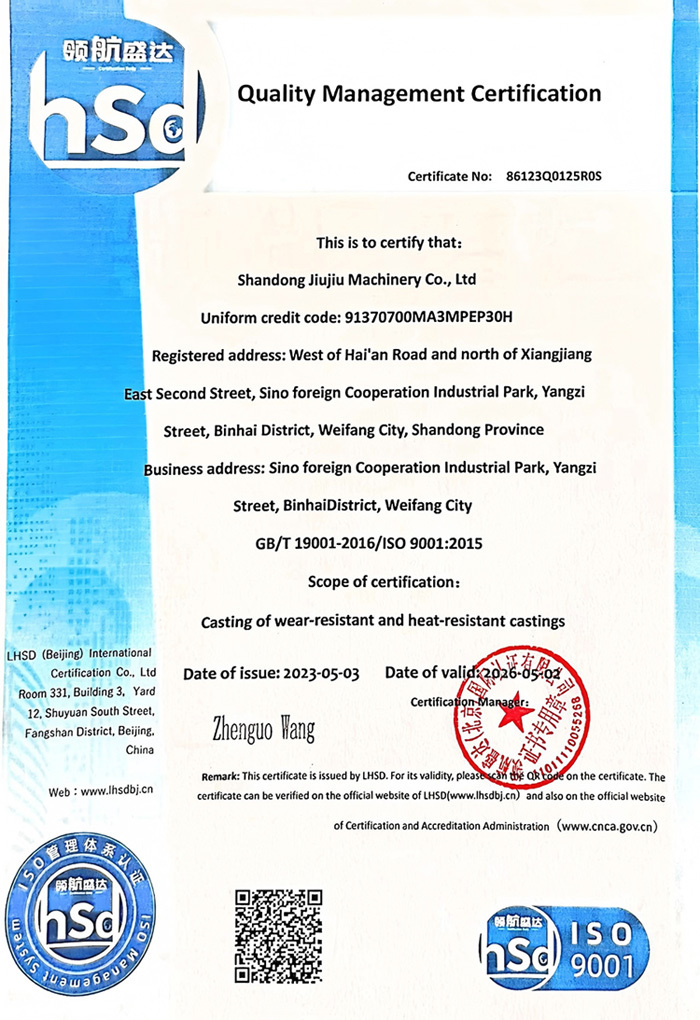

Inspections & Certifications

Certifications

Certifications

Customer visits

Customer visits

Customer visits

Customer visits

Customer visits

Keywords

impact plates for impact crusher

impact plates for impact crusher

Contact Us

Telephone:+86-13792621099

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products