Category

Product Description

The plate of the roll crusher is the core wear-resistant component that directly contacts the material. These plates not only cooperate with the crusher’s rolling mechanism to squeeze and crush coal, ore, limestone, etc., but also serve as protective liner plates for the roll body. They prevent direct wear of the roll core, extending the crusher’s service life.

The plate is usually cast with high manganese steel or alloy steel, and the surface is processed with serrated or wavy convex structures. This tooth design can enhance the bite force and shear effect on the material, and is especially suitable for processing medium-hard materials such as coal and limestone. Under high-intensity working conditions, the plate will use materials such as chromium-molybdenum alloy to improve wear resistance, or strengthen the wear-resistant layer at the tip of the tooth through surfacing welding.

Casting process: lost foam casting

Applicable machines: crusher

Applicable industries: mining, coal, steel, cement plants, etc.

Material types: high manganese steel

Chemical composition % of high manganese steel

This product is a customized product and is produced according to customer drawings or samples.

Casting Process

Casting Process

Casting Process

Casting Process

Casting Process

Delivery site

Delivery site

Delivery site

Delivery site

Delivery site

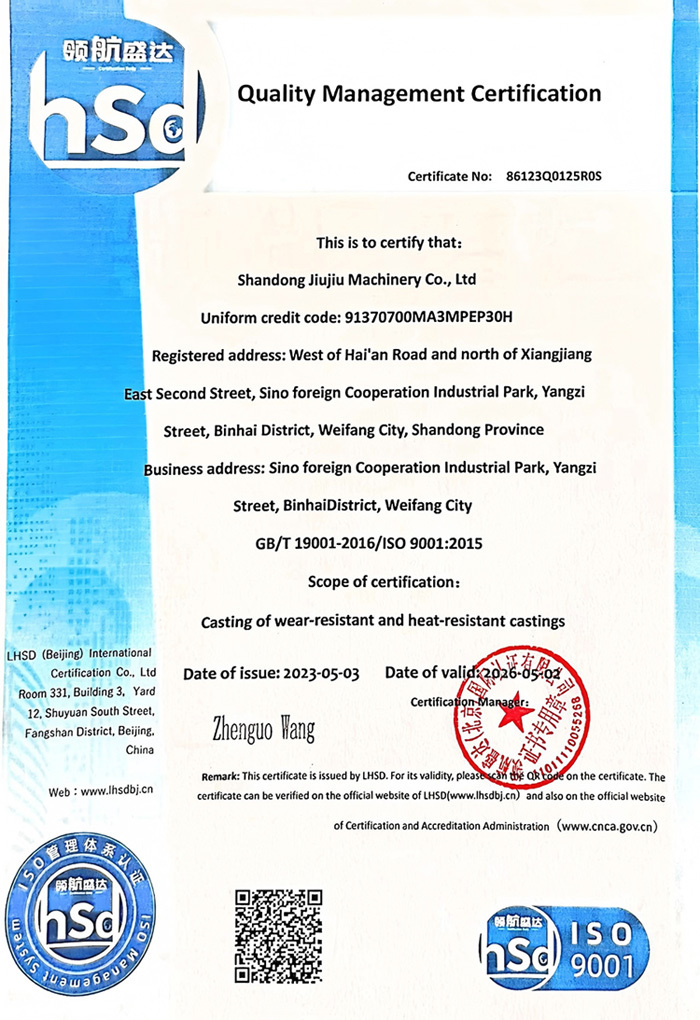

Inspections & Certifications

Certifications

Certifications

Customer visits

Customer visits

Customer visits

Customer visits

Customer visits

Keywords

plate for roll crusher

plate for roll crusher

Contact Us

Telephone:+86-13792621099

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products