The material selection of the crusher hammer directly affects the efficiency and service life of the equipment, and the wear resistance, toughness and working conditions need to be considered comprehensively. The current mainstream materials include high manganese steel, high chrome cast iron, alloy steel and composite materials, each of which has its own applicable scenarios.

High manganese steel is a traditional preferred material, and its biggest feature is its excellent impact hardening properties. When subjected to strong impact, a hardened layer will form on the surface, which significantly improves the wear resistance, while the interior still maintains good toughness, which can effectively prevent fracture. This material is particularly suitable for processing materials with high hardness and high impact, such as granite, iron ore, etc., and performs outstandingly in large impact crushers.

High chrome cast iron is known for its ultra-high wear resistance, with a hardness of more than HRC60, and is suitable for fine crushing operations with strong abrasiveness. Its chromium carbide hard phase can greatly extend the life of the hammer, but it is highly brittle and needs to be used in conditions with less impact. It is commonly used in small and medium-sized hammer crushers that process limestone and coal gangue. In order to balance performance, it is often used in combination with tough materials.

Alloy steel improves its comprehensive performance by adding elements such as chromium and molybdenum. It has both high hardness and moderate toughness and is suitable for working conditions with medium impact strength. Its advantage is that the performance parameters can be flexibly adjusted through heat treatment, which makes it more adaptable in scenarios with variable material properties and has a relatively balanced cost performance.

The new composite material adopts a gradient structure or a bimetallic composite process to combine a high-hardness surface layer with a tough matrix, which can resist wear and absorb impact energy. This type of material can extend its life by 2-3 times in special working conditions, but the cost is high and it is mostly used in key equipment or long-term continuous operation scenarios.

The actual material selection needs to comprehensively consider the material hardness, crusher type and maintenance cost. It is recommended to give priority to high manganese steel in high impact conditions, high chromium cast iron for strong wear and fine crushing, alloy steel for ordinary conditions, and composite materials for high-demand occasions. Reasonable material selection can increase crushing efficiency by more than 30%, while reducing ton consumption cost, which is an important part of equipment optimization.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

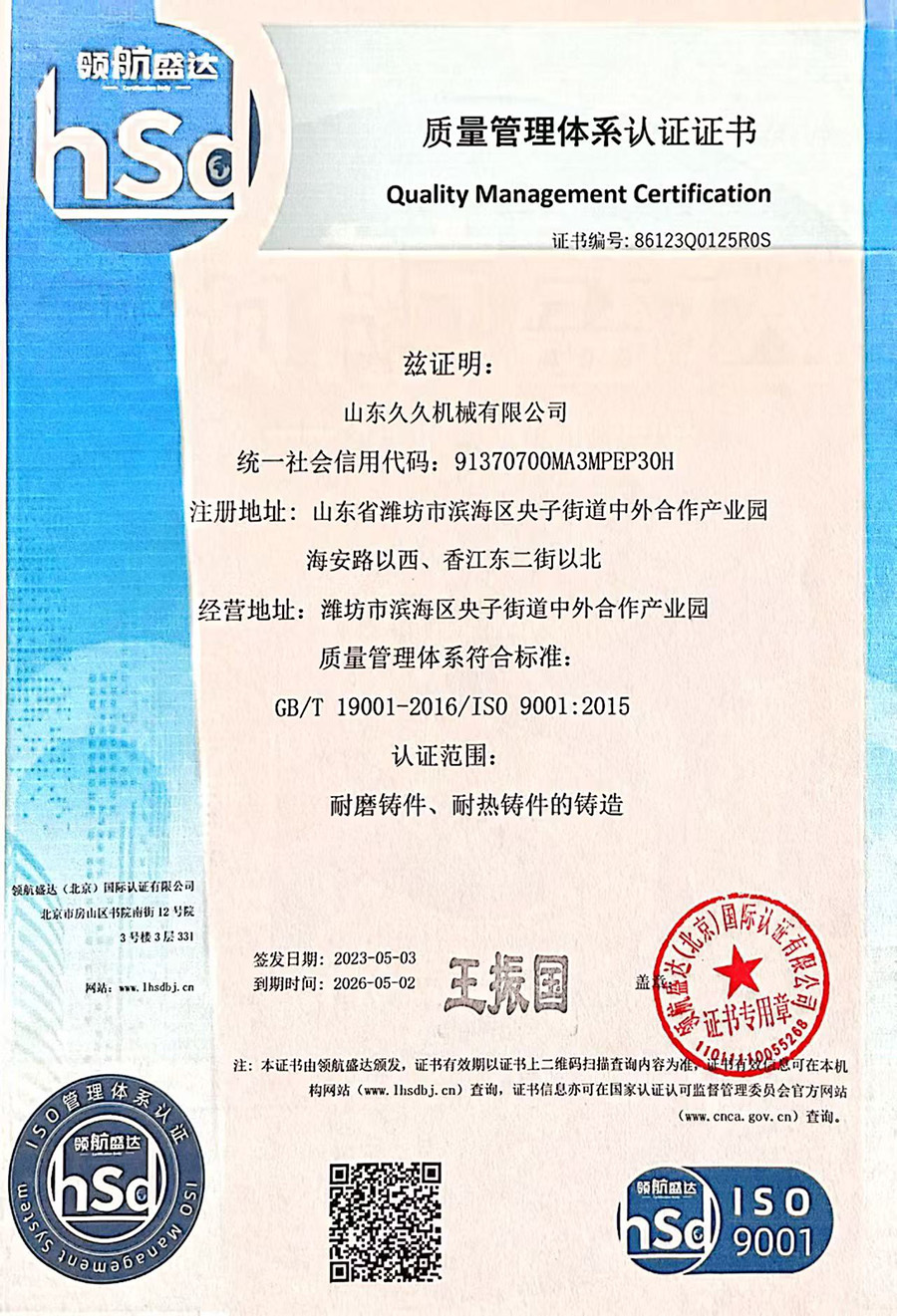

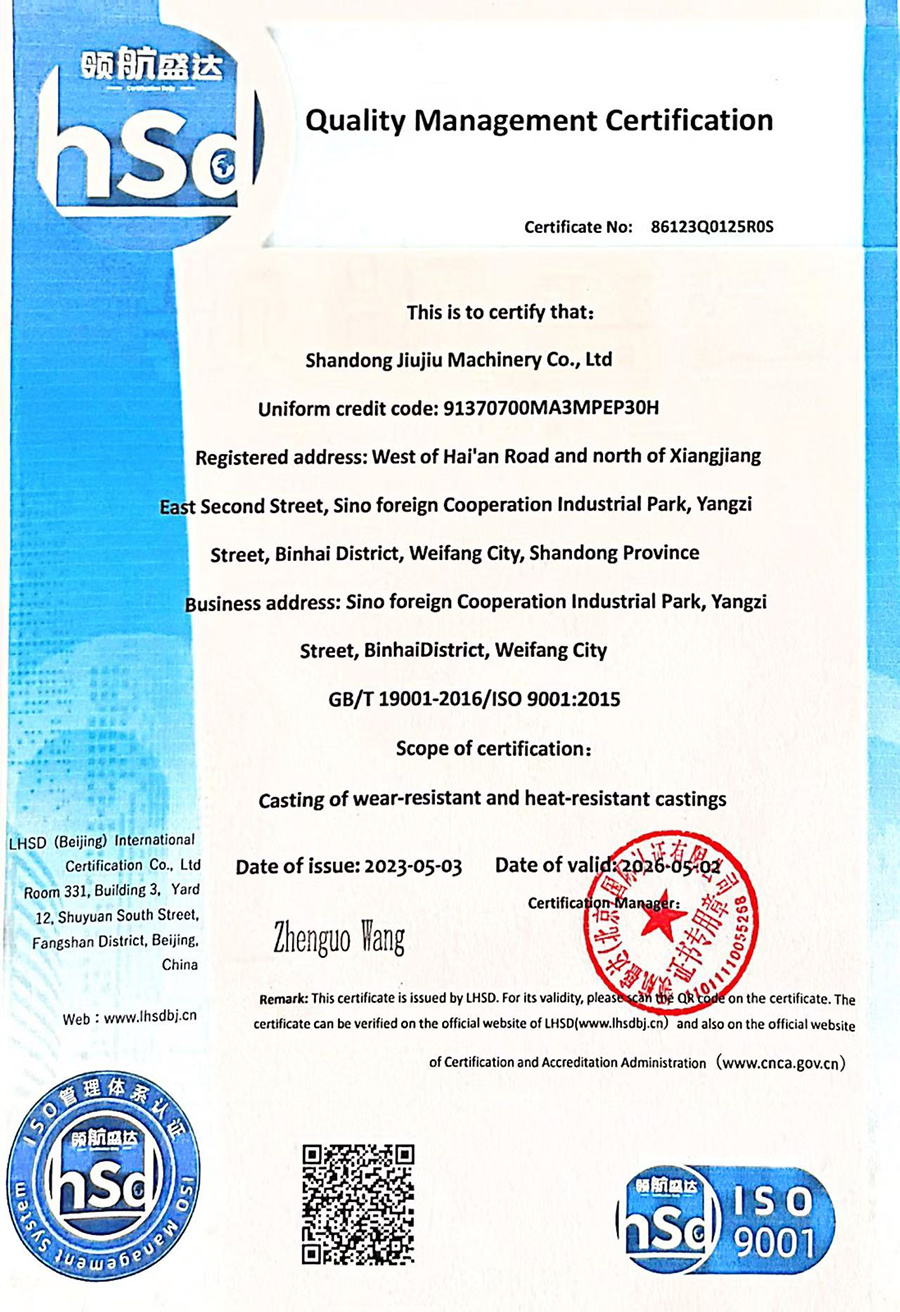

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

blow bars

blow bars

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products