The blow bar of the impact crusher is mainly suitable for the secondary crushing process of medium and high hardness materials. Its unique structural design and material characteristics make it perform well under specific working conditions. This type of blow bar crushes materials through the impact kinetic energy generated by high-speed rotation. It is particularly suitable for processing limestone, basalt, granite and other stones with a compressive strength between 150-350MPa. Compared with primary crushing equipment such as jaw crushers, the blow bar of the impact crusher pays more attention to the cubic forming effect of the material, so it is widely used in fields with strict requirements on particle shape such as building aggregates and highway cushions.

From the perspective of adaptability to working conditions, the blow bar of the impact crusher is most suitable for processing dry materials with a moisture content of less than 8%. Over-wet materials are prone to cause plate blow bar sticking and affect efficiency. In terms of equipment matching, it is recommended to use it for medium and large impact crushers (rotor diameter above 800mm) with a rotor linear speed of 30-50m/s, and the processing capacity is preferably 100-500 tons per hour. In terms of material selection, high-chromium cast iron blow bars are suitable for highly abrasive materials, while composite blow bars can take into account both hardness and toughness. It should be noted that when the material contains more than 5% of metal impurities such as iron blocks, the life of the blow bar will be significantly shortened. At this time, an iron removal device should be installed.

Typical application scenarios include: medium and fine crushing of sand and gravel aggregate production lines, concrete crushing for construction waste recycling, and pre-grinding processes in mine dressing plants. Its advantage is that it can guarantee both output and particle shape, but the maintenance cost is high, and the position of the worn blow bar needs to be replaced regularly to extend the overall service life. For working conditions that process sticky materials or super-hard ores (compressive strength > 350MPa), it is recommended to use other crushing solutions.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

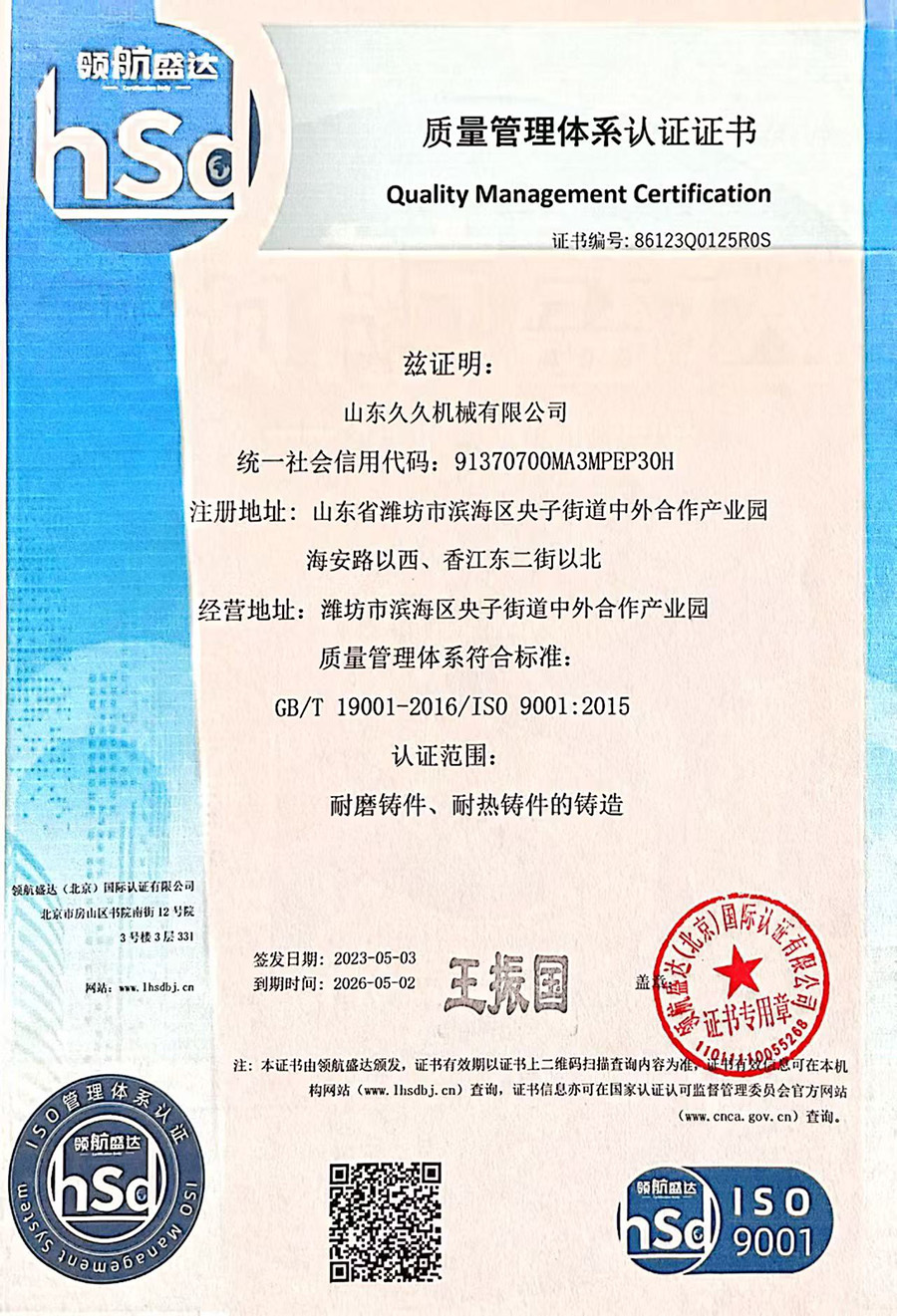

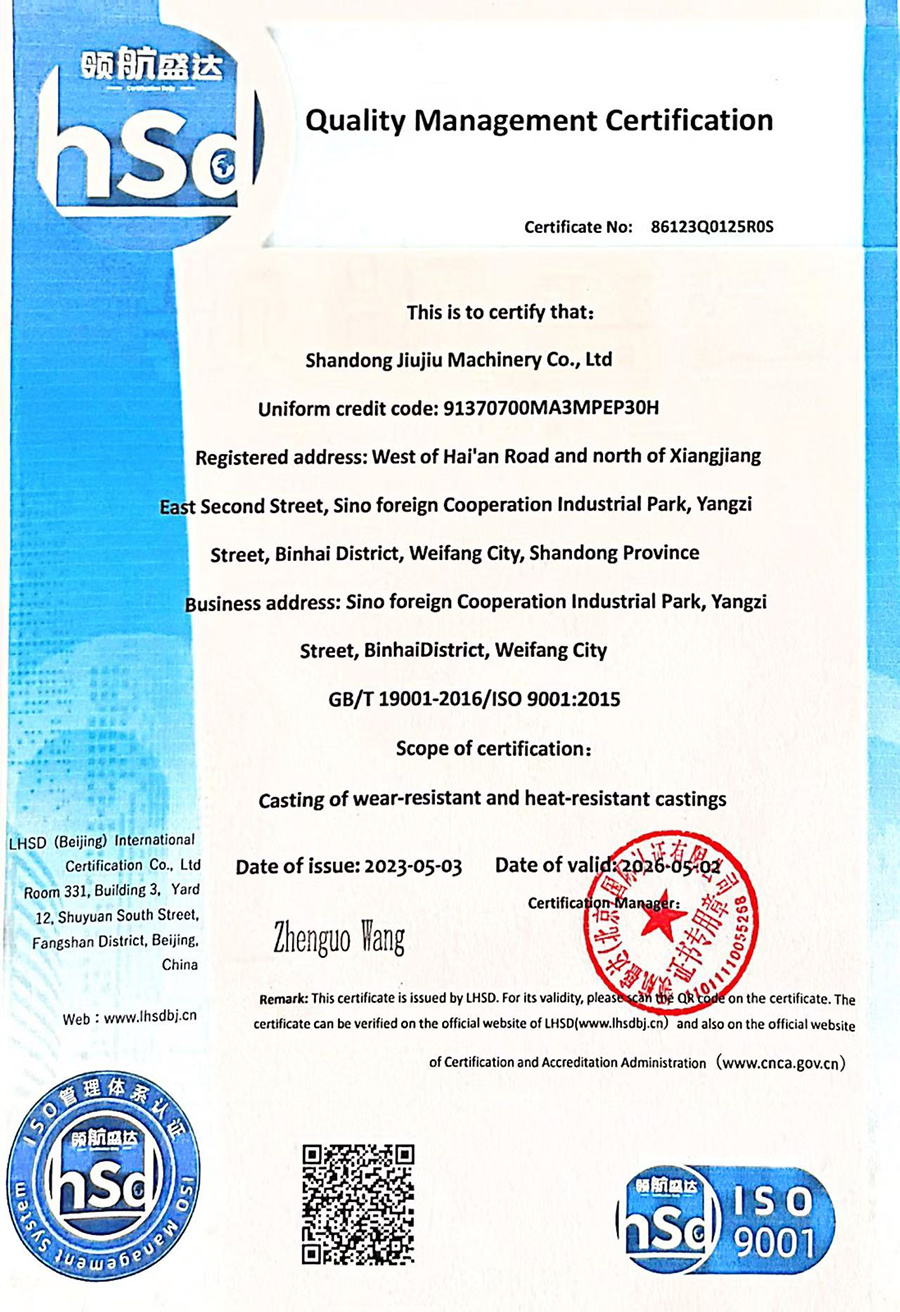

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

impact crusher blow bars

impact crusher blow bars

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products