The chromium-containing crusher blow bar is suitable for severe crushing conditions with high wear and high impact. This type of blow bar forms high-hardness carbide by adding chromium, which is particularly suitable for processing super-hard and highly abrasive materials such as granite, basalt, and iron ore. Its core advantage is that its wear resistance far exceeds that of ordinary manganese steel blow bars, and it can still maintain sharp edges under continuous impact, and the crushing efficiency is significantly improved.

Typical application scenarios include: the main crushing section of a large sand and gravel aggregate production line, the primary crushing process of a metal ore beneficiation plant, and a fixed crushing station that requires long-term continuous operation. Compared with manganese steel blow bars, high-chromium blow bars are more suitable for large-volume conditions of more than 300 tons per hour, but their toughness is relatively low, so they are not recommended for crushing materials containing foreign metal impurities such as steel slag. In terms of economy, although the purchase cost of a single piece is high, its life can reach 2-3 times that of a manganese steel blow bar, and the comprehensive benefits are significant in large-scale production.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

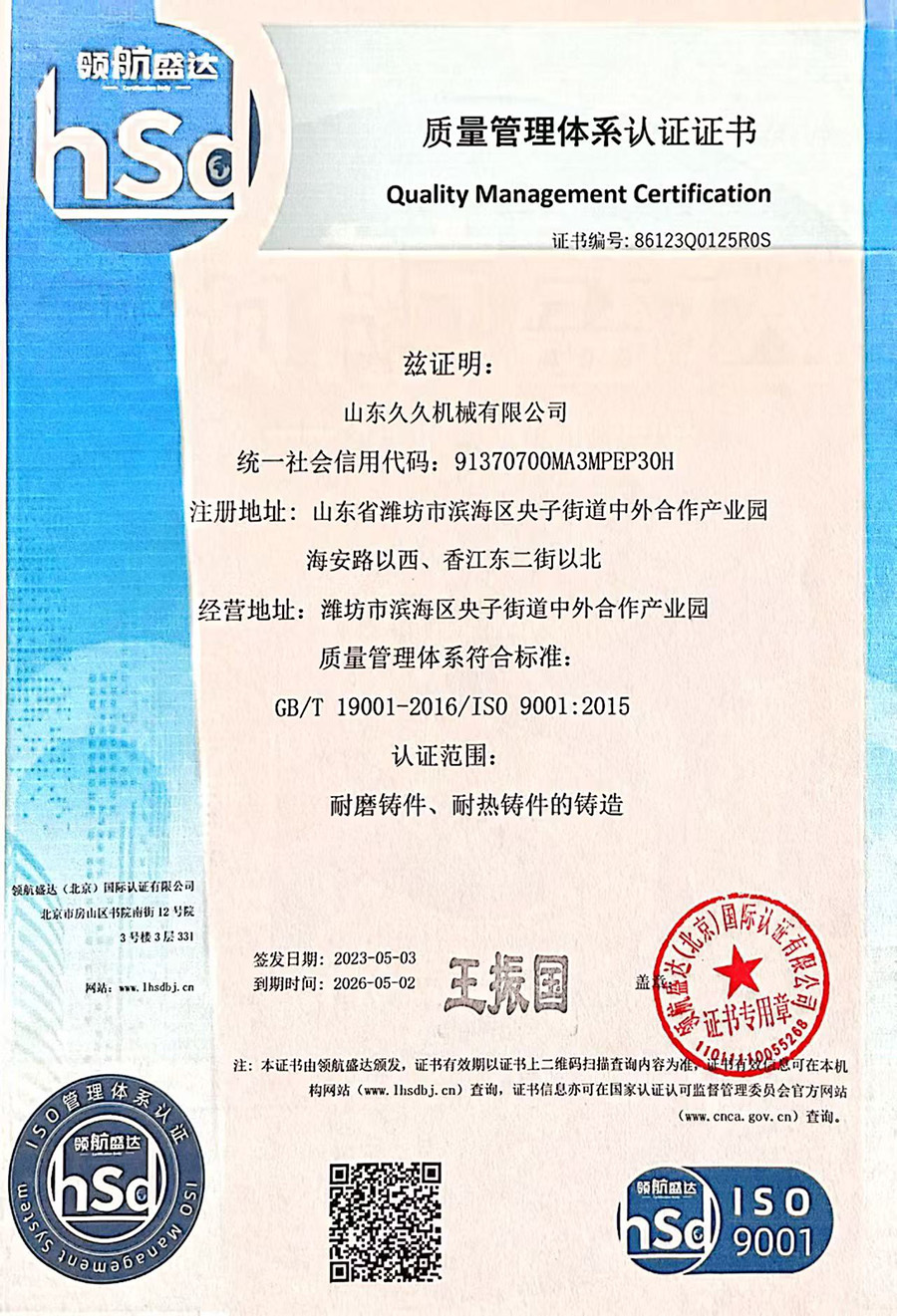

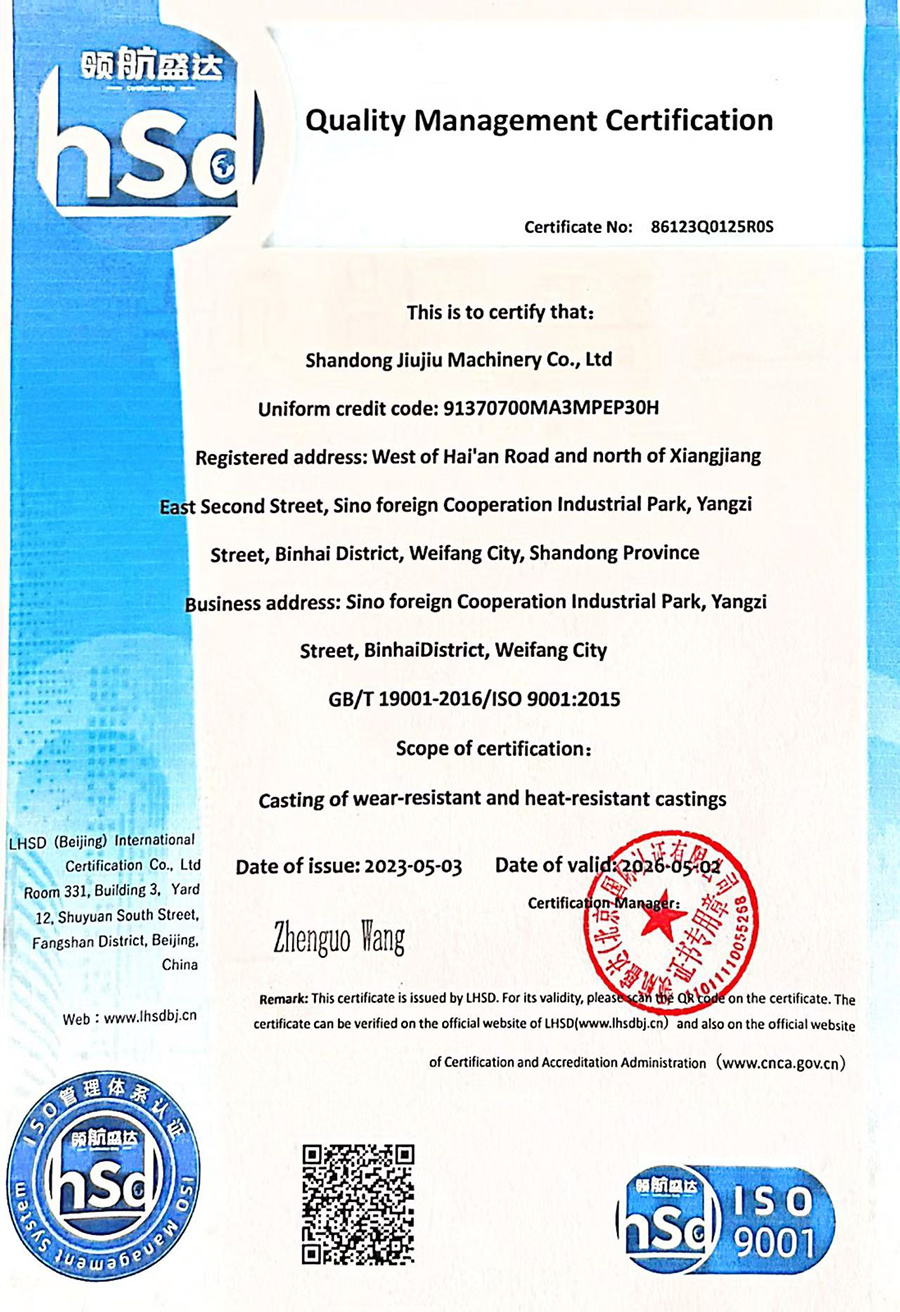

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

crusher blow bars

crusher blow bars

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products