The manufacturing process of crusher liner plate is a comprehensive process that combines material science, foundry technology, and precision machining to create high-quality products that are both wear-resistant and impact-resistant. This process is very particular from the beginning of material selection. Usually, manufacturers will choose high-performance materials such as high chrome cast iron, manganese steel, or special alloy steel, which are ideal for crusher linings with their excellent hardness, wear resistance, and toughness.

After material selection, it enters the casting stage. Before casting, the raw materials need to undergo strict chemical composition analysis and quality control to ensure that each batch of materials meets the design requirements. Then, advanced casting techniques such as investment casting or sand casting are used to inject molten metal into a pre-designed mold. In this process, temperature control, casting speed and cooling rate are all crucial, which directly affect the internal structure and final performance of the liner.

After casting, the liner plate needs to undergo a series of heat treatment and surface strengthening processes. Heat treatment includes steps such as quenching and tempering, which are aimed at further adjusting the material's structure and improving its hardness and toughness. Surface strengthening may include techniques such as sandblasting, carburizing or coating with a wear resistant layer to enhance the wear and corrosion resistance of the surface of crusher liner plate .

Then, it enters the precision machining stage. Using high-precision equipment such as CNC machine tools and grinders, the liner plate is precisely dimensioned and shaped to ensure that it fits perfectly with other parts of the crusher. In addition, the surface of the crusher liner plate is polished to reduce friction with the material and improve crushing efficiency.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

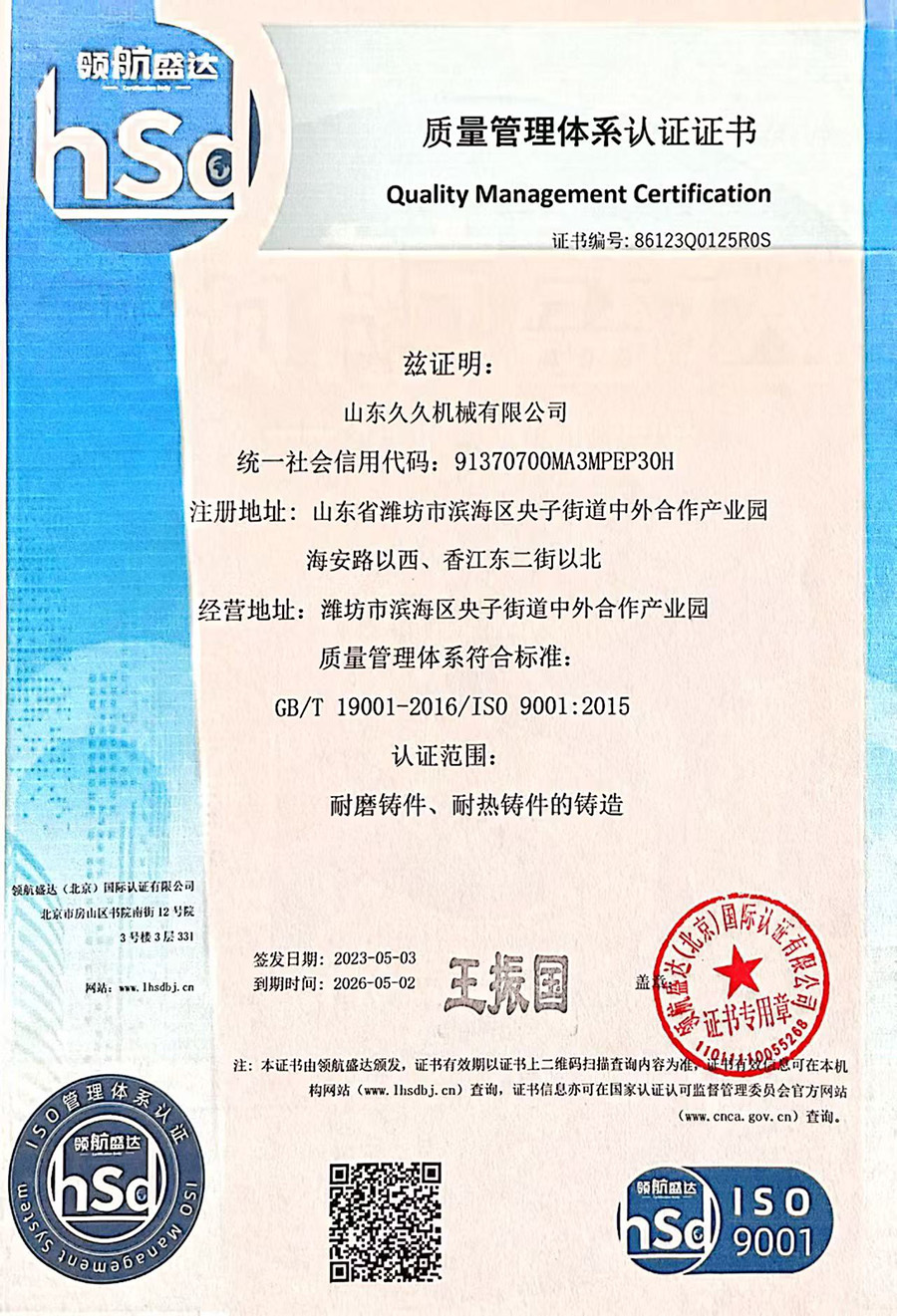

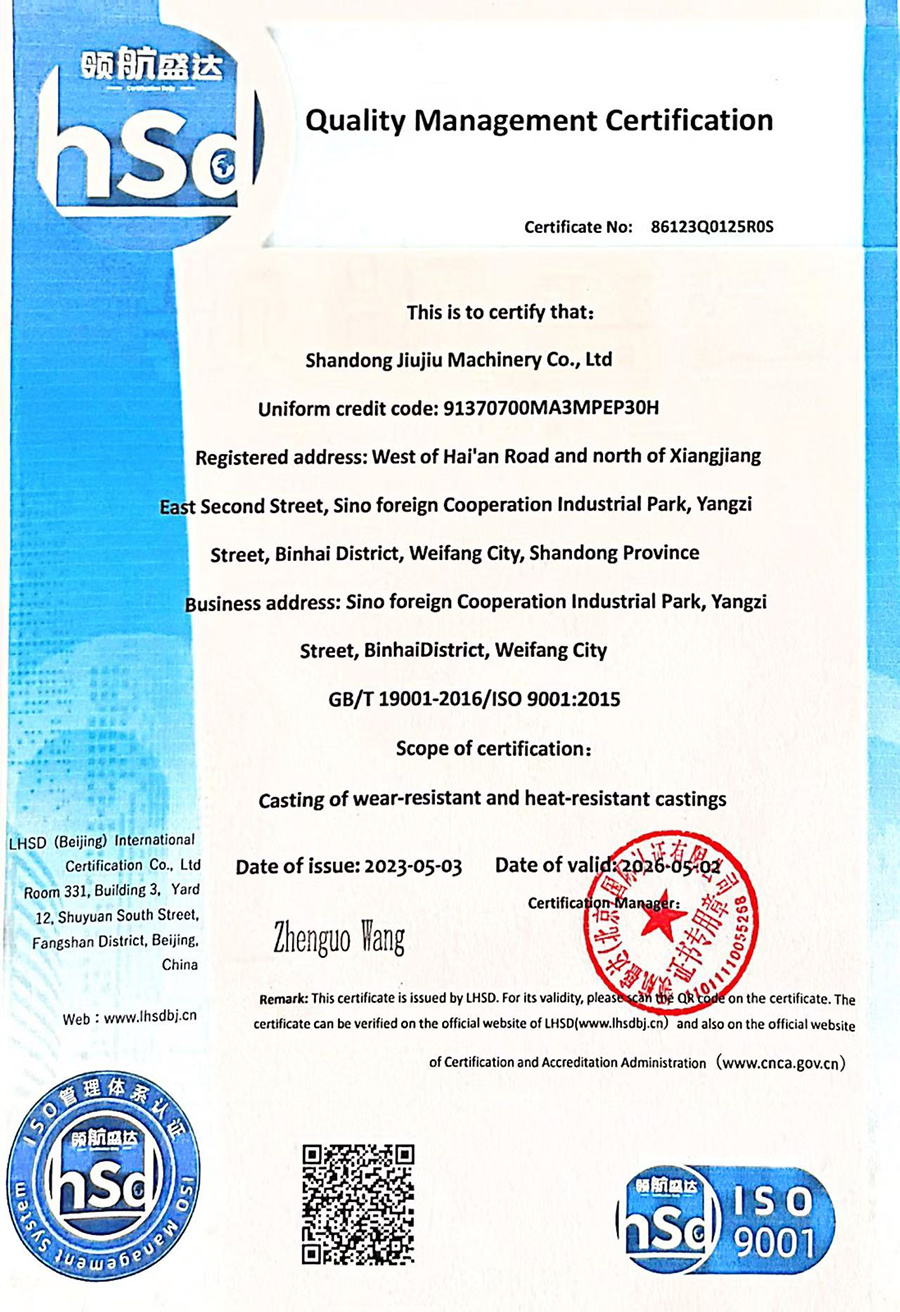

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

crusher liner plate

crusher liner plate

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products