As the preferred material for the core components of crushers, manganese steel plays an irreplaceable role in the vulnerable parts of various crushing equipment with its excellent impact resistance and wear resistance. This type of alloy steel forms a high-toughness austenite structure through special heat treatment during the manufacturing process, which enables it to produce a surface hardening effect under severe impact, which not only relieves instantaneous stress but also delays the wear process. For example, on the movable jaw plate and fixed jaw plate of the jaw crusher, the ductility of manganese steel effectively absorbs the vibration energy generated by the bite and crushing of large pieces of ore to avoid brittle fracture; and on the surface of the hammer of the impact crusher, the wear-resistant layer of manganese steel can withstand repeated collisions with materials under high-speed rotation, significantly extending the replacement cycle. For the rolling wall and crushing wall of the cone crusher, the microscopic grain structure of manganese steel forms a self-repairing hardened layer in continuous extrusion and friction, which not only maintains the geometric accuracy of the crushing chamber but also reduces power consumption.

In harsh working conditions such as mining and construction aggregates, the fatigue resistance of manganese steel components makes them suitable for high-intensity continuous operation. When the hardness of the material fluctuates, its unique cold work hardening characteristics will further increase the surface hardness as the frequency of impact increases, forming a dynamic protection mechanism. This "harder with use" characteristic makes manganese steel particularly suitable for crushing scenarios involving highly abrasive materials such as granite and basalt. At the same time, the weldability and casting flexibility of manganese steel facilitate the customized production of special-shaped parts. For example, complex structural parts such as crusher screen bars and liners can achieve a balance between performance and cost through precision casting. Although composite wear-resistant materials are still needed as a supplement under extreme impact, manganese steel still maintains a fundamental position in the field of crushing equipment. Its combined advantages of economy and reliability make it a key solution for balancing equipment life and operation and maintenance costs.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

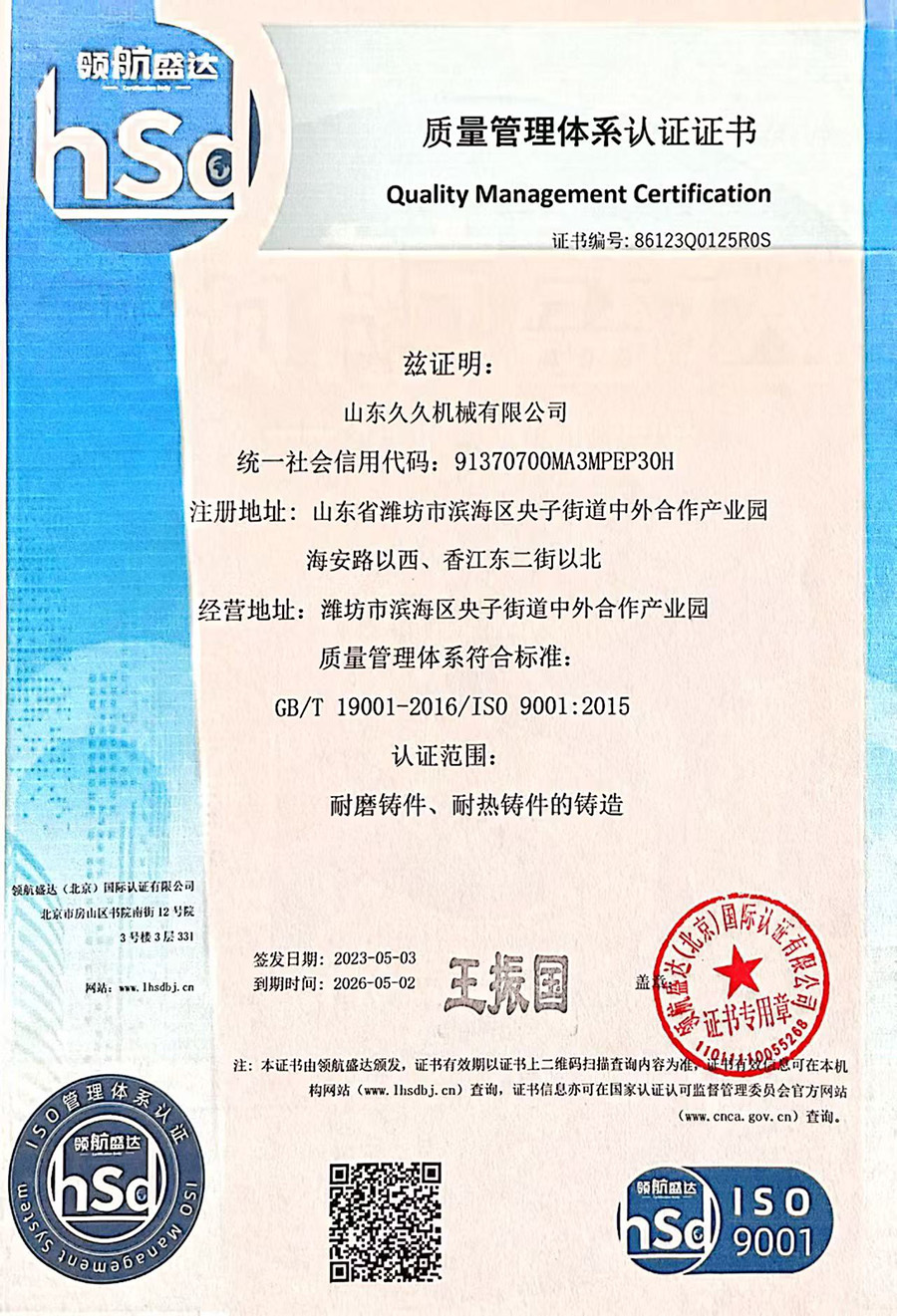

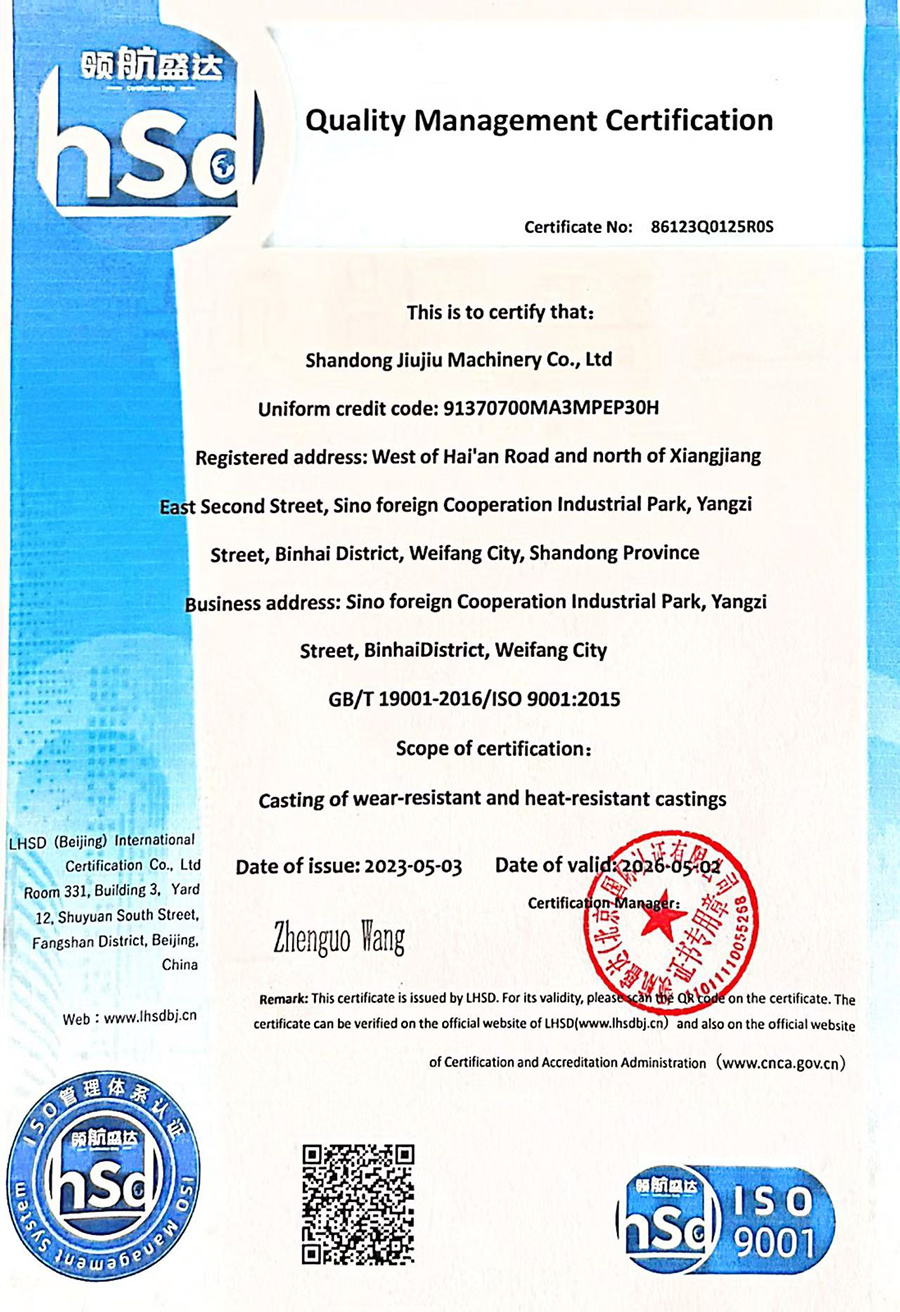

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Manganese steel for crusher

Manganese steel for crusher

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products