The grate bar of the garbage incinerator is one of the core components in the municipal solid waste incineration system. Its design and operation quality directly affect the incineration efficiency, energy recovery rate and pollutant emission control level. As a key structure in the garbage transportation and combustion process in the incinerator, the grate system needs to have multiple characteristics such as high strength, high heat resistance and corrosion resistance, and at the same time, it must meet the process requirements of dynamic turning and uniform combustion of the garbage layer.

I. Structural and functional design

The grate system is usually composed of several groups of parallel arranged strip components, and the modular design is easy to maintain and replace. The width of each grate bar is between 150-300 mm, and the thickness is designed to be in the range of 30-80 mm according to the heat load. Its surface is designed with a special convex structure, which not only enhances the friction with the garbage layer, but also forms a ventilation gap to promote oxygen penetration. Modern incinerator grates mostly adopt a reciprocating motion design, and the "push-turn-crush" trinity movement of the garbage layer is realized through hydraulic drive. This dynamic process keeps the thickness of the garbage layer uniform and avoids local overheating or incomplete combustion.

II Material science and thermodynamic challenges

Grate bars need to work for a long time in a high temperature environment of 850-1100℃, and the material selection needs to meet the requirements of extreme working conditions. The mainstream material uses high chromium nickel alloy or silicon carbide composite material, whose high temperature strength can reach more than 60% of normal temperature, and thermal shock resistance ΔT>400℃. In terms of surface treatment technology, plasma spraying alumina-zirconia composite coating can increase wear resistance by 3-5 times, effectively dealing with the wear problem caused by glass and metal fragments in garbage. Thermal stress simulation shows that the optimized wavy grate bar structure can reduce thermal deformation by 27%, significantly extending the service life.

III. Fluid mechanics and combustion control

The secondary air channel formed by the grate bar gap accounts for 30%-40% of the total air supply, and its opening rate is precisely controlled within the range of 15%-25%. Through CFD simulation, it was found that the V-shaped grate bar arrangement can extend the flue gas residence time by 0.8-1.2 seconds, promoting the full decomposition of dioxin substances. The intelligent control system dynamically adjusts the moving speed and air volume ratio according to the temperature field distribution of the grate layer, so as to stabilize the temperature of the combustion zone within the fluctuation range of ±20℃ and ensure the environmental protection standard of 850℃/2 seconds.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

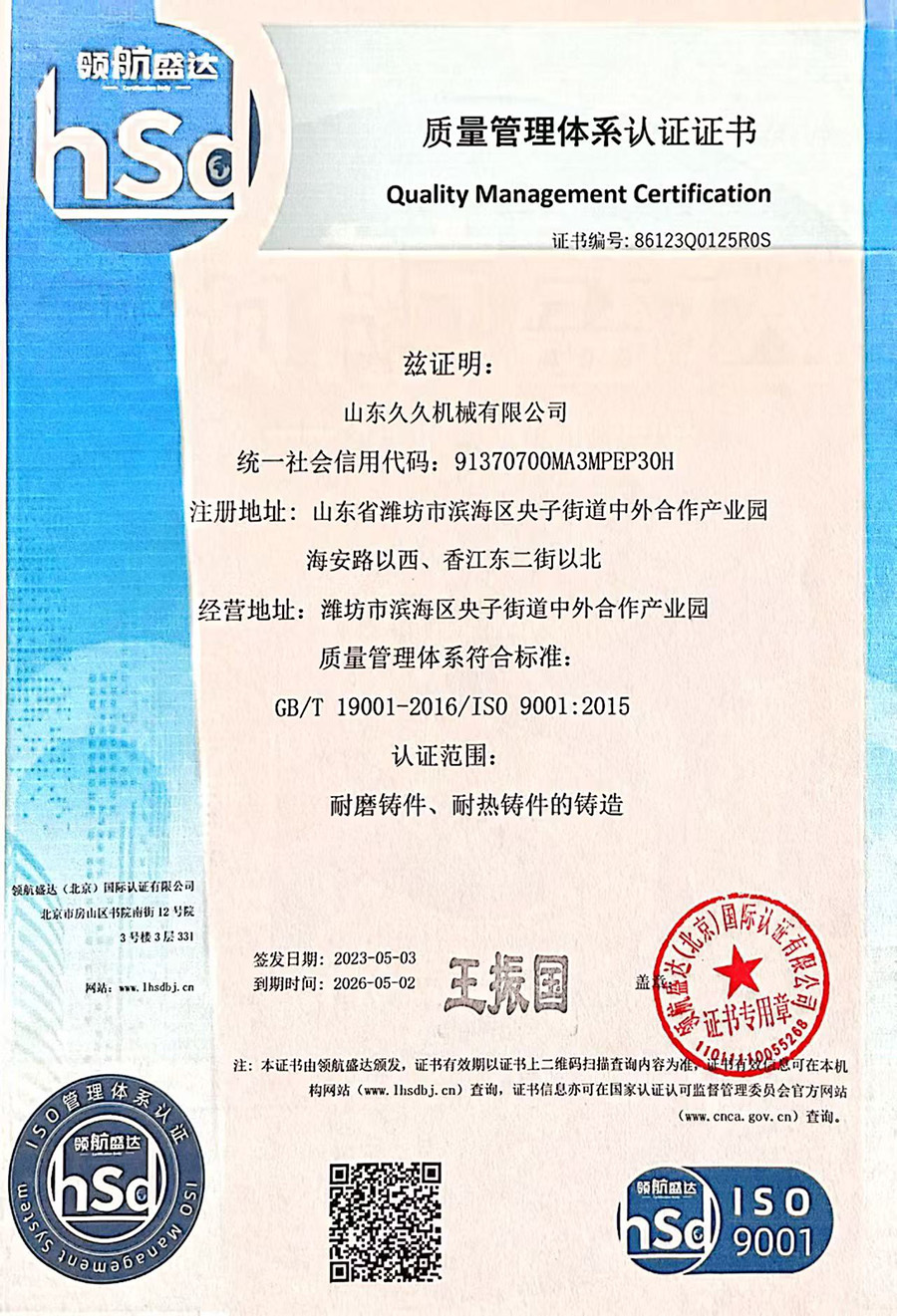

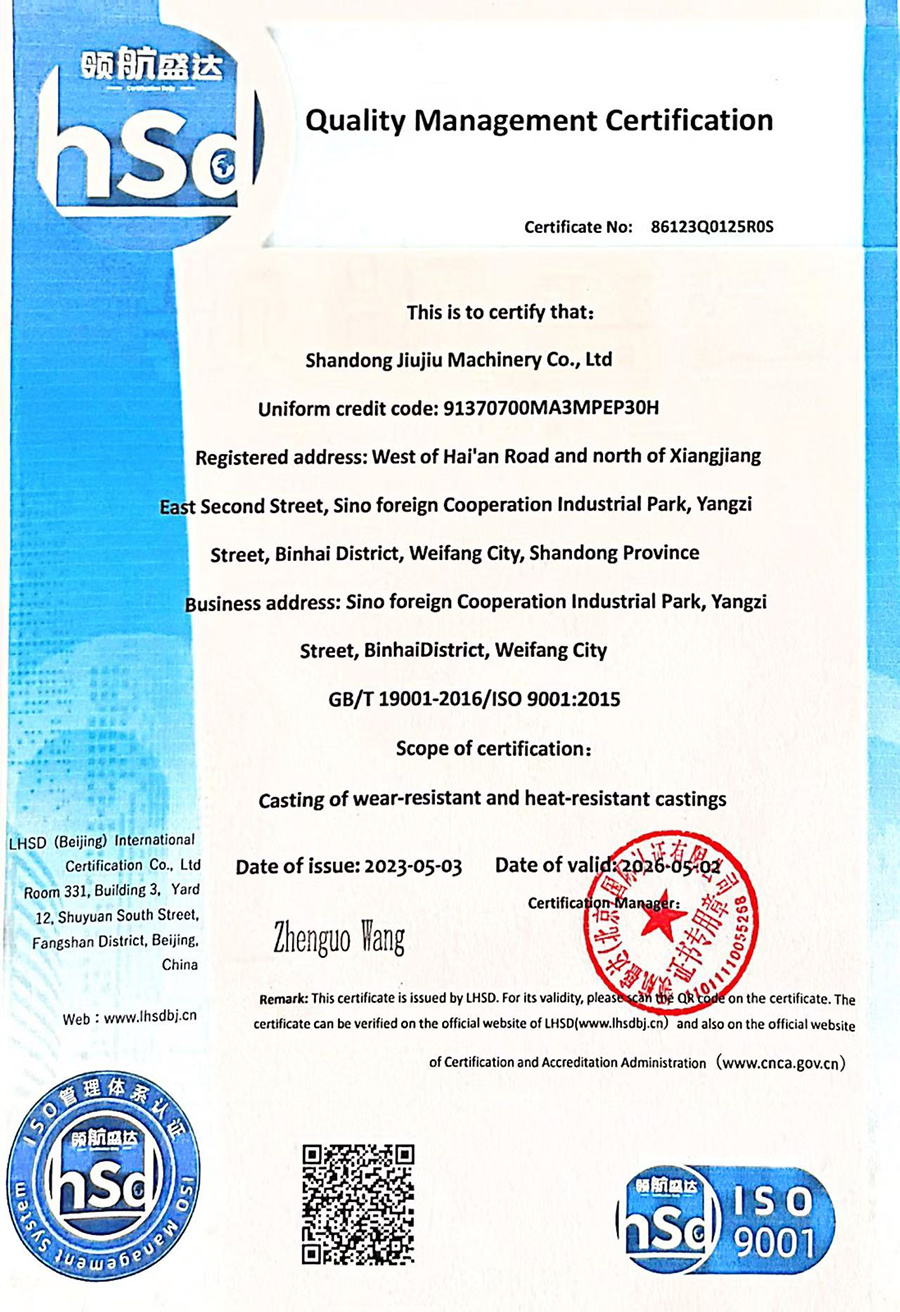

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Incinerator grate bars

Incinerator grate bars

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products