The impact crusher hammer is the core working component of this type of crushing equipment, and it is responsible for the high-efficiency impact crushing of materials. It is not only a key component that directly acts on the material to cause it to break and crush, but also one of the main components that bears huge impact force and wear during the entire crushing process.

The hammer is usually made of high-strength, high-hardness and wear-resistant alloy steel or special cast steel materials. These materials can ensure that the hammer can still maintain good mechanical properties and wear resistance under long-term high-intensity working conditions. Its structural design is scientific and reasonable, which not only ensures sufficient impact force, but also effectively disperses stress to prevent fracture or deformation due to long-term impact.

During the working process of the impact crusher, the hammer violently hits the material entering the crushing chamber in a high-speed rotating manner, causing the material to be instantly subjected to huge impact force and break. At the same time, the shape and arrangement of the hammer are also carefully designed to ensure that the material can be evenly and effectively crushed, so as to obtain ideal particle size distribution and product quality.

In order to further improve the wear resistance and service life of the hammer head, modern impact crusher hammer heads often use advanced heat treatment processes and surface strengthening technologies, such as quenching, carburizing, and surfacing wear-resistant alloys. These technologies can not only significantly improve the hardness and wear resistance of the hammer head, but also enhance its impact resistance and fatigue resistance, thereby extending the service life of the hammer head and reducing the maintenance cost of the equipment.

The impact crusher hammer is an indispensable key component in the crushing equipment, and its performance directly affects the crushing efficiency, product quality and operating cost of the equipment. Therefore, when selecting and using the hammer head, its material, structural design, manufacturing process, and maintenance management must be fully considered to ensure the efficient and stable operation of the equipment and long-term economic benefits.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

Quality Inspection Certificate

Quality Inspection Certificate 2

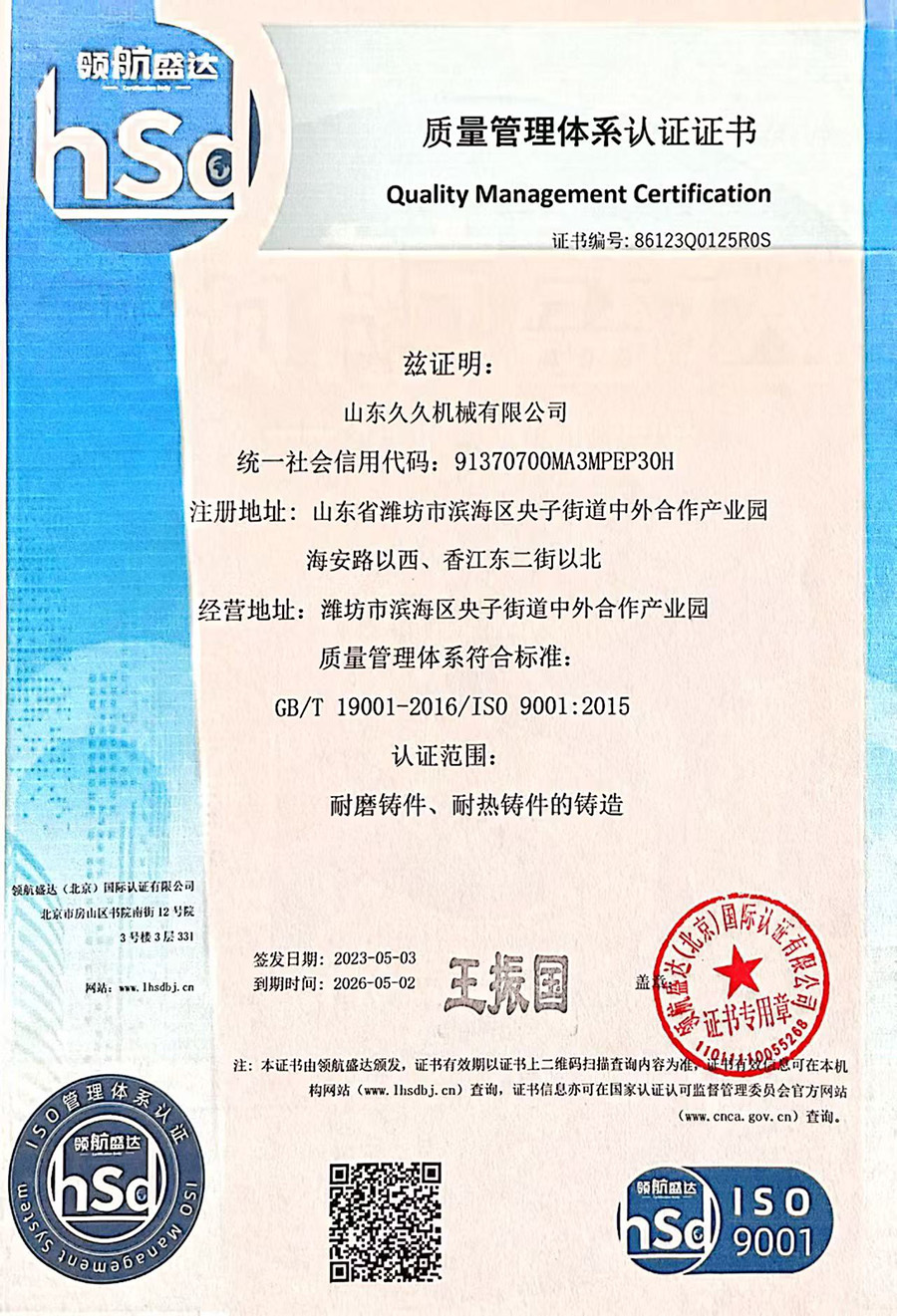

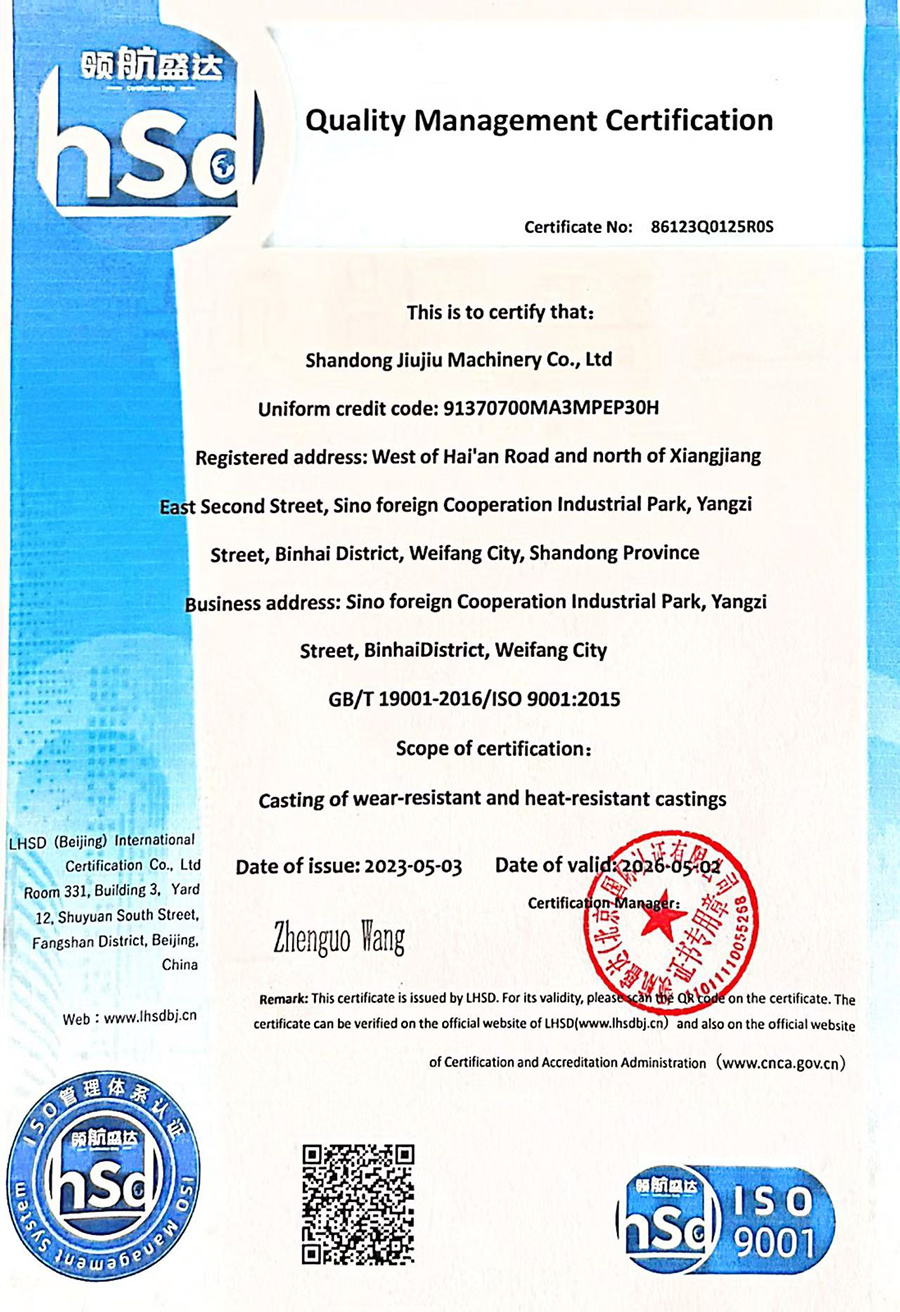

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Impact crusher hammer

Impact crusher hammer

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products