The grate bars of boilers and furnaces are key structures that support fuel combustion. Their design needs to maintain stable operation in a complex environment of high temperature, wear and corrosion. Traditional grate bars are mostly cast with cast iron or ordinary steel, and the surface is arranged in strips or sheets to form a uniform ventilation gap. This structure can not only provide a stable combustion platform for the fuel, but also promote full combustion through the penetration of bottom air. However, ordinary materials are prone to oxidation and embrittlement under long-term high temperatures, especially in the acidic corrosive environment of biomass fuel or high-sulfur coal, and pits or cracks are prone to occur on the surface of the grate bars, resulting in uneven ventilation, fuel leakage and other problems.

In order to cope with more stringent working conditions, modern grate bars are gradually made of high chrome alloy or heat resistant steel. This type of material significantly improves its anti-oxidation and anti-deformation capabilities by optimizing the ratio of metal elements. For example, in coal-fired boilers, grate bars need to withstand repeated friction of fuel and impact of ash slag, and the hardness and wear resistance of high chrome alloys can extend their service life. In waste incinerators, grate bars also need to resist the erosion of corrosive gases such as chlorine and sulfide. At this time, surface coating or composite materials become necessary choices, such as cladding a nickel-based alloy layer on the base steel to form double protection.

The material and shape innovation of grate bars directly affect the combustion efficiency and environmental performance of boilers and furnaces. Corrosion-resistant materials reduce air leakage caused by structural damage and maintain combustion stability; optimizing ventilation gaps improves oxygen utilization and reduces harmful gases produced by incomplete combustion. These improvements not only reduce equipment maintenance costs, but also provide a structural basis for clean energy adaptation, such as significantly improving the combustion efficiency of biomass pellets or waste-derived fuels. It can be said that although grate bars seem simple, they play the dual roles of "load bearing" and "regulation" in the thermal energy conversion system, and are an important carrier for the continuous upgrading of combustion technology.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

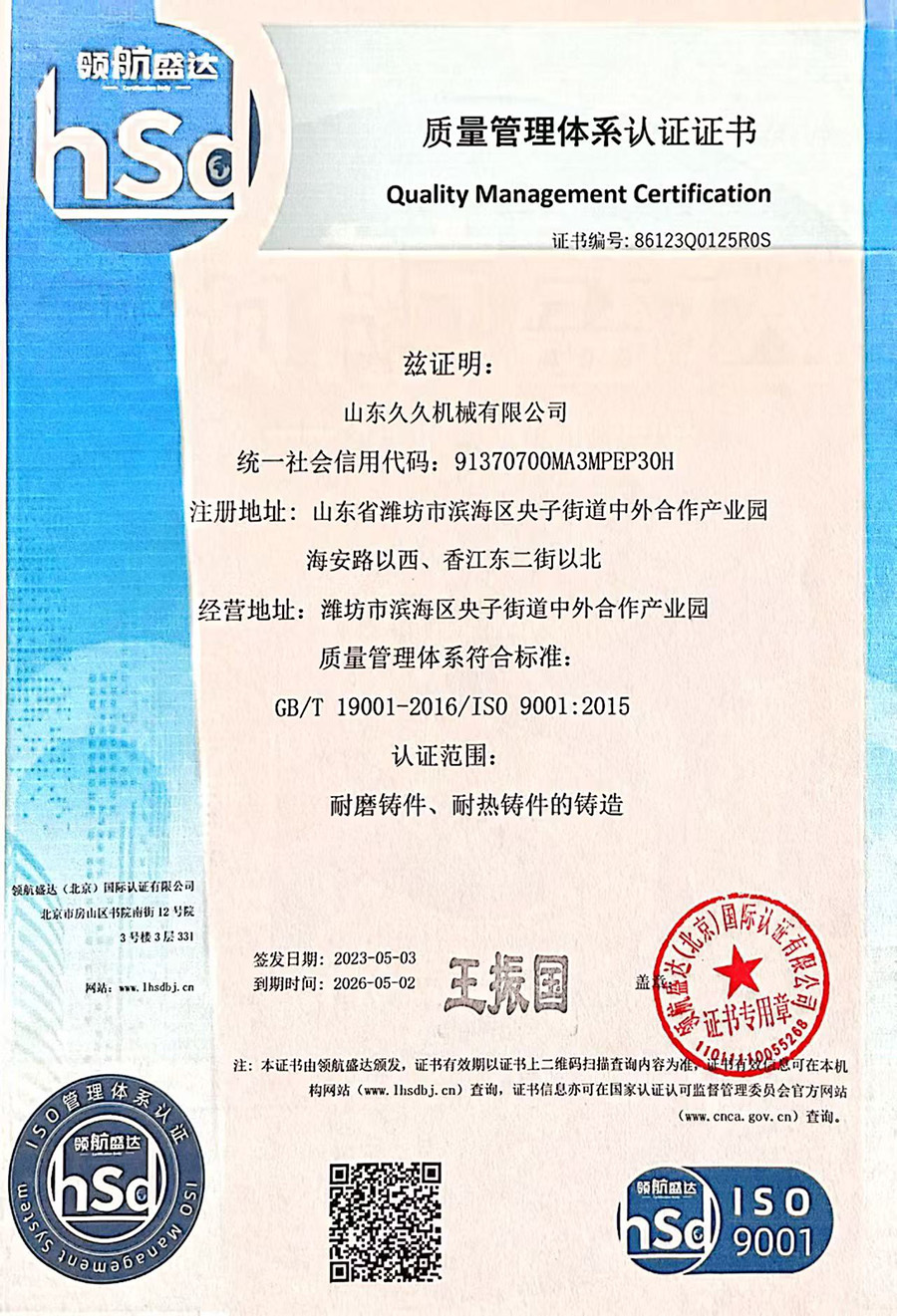

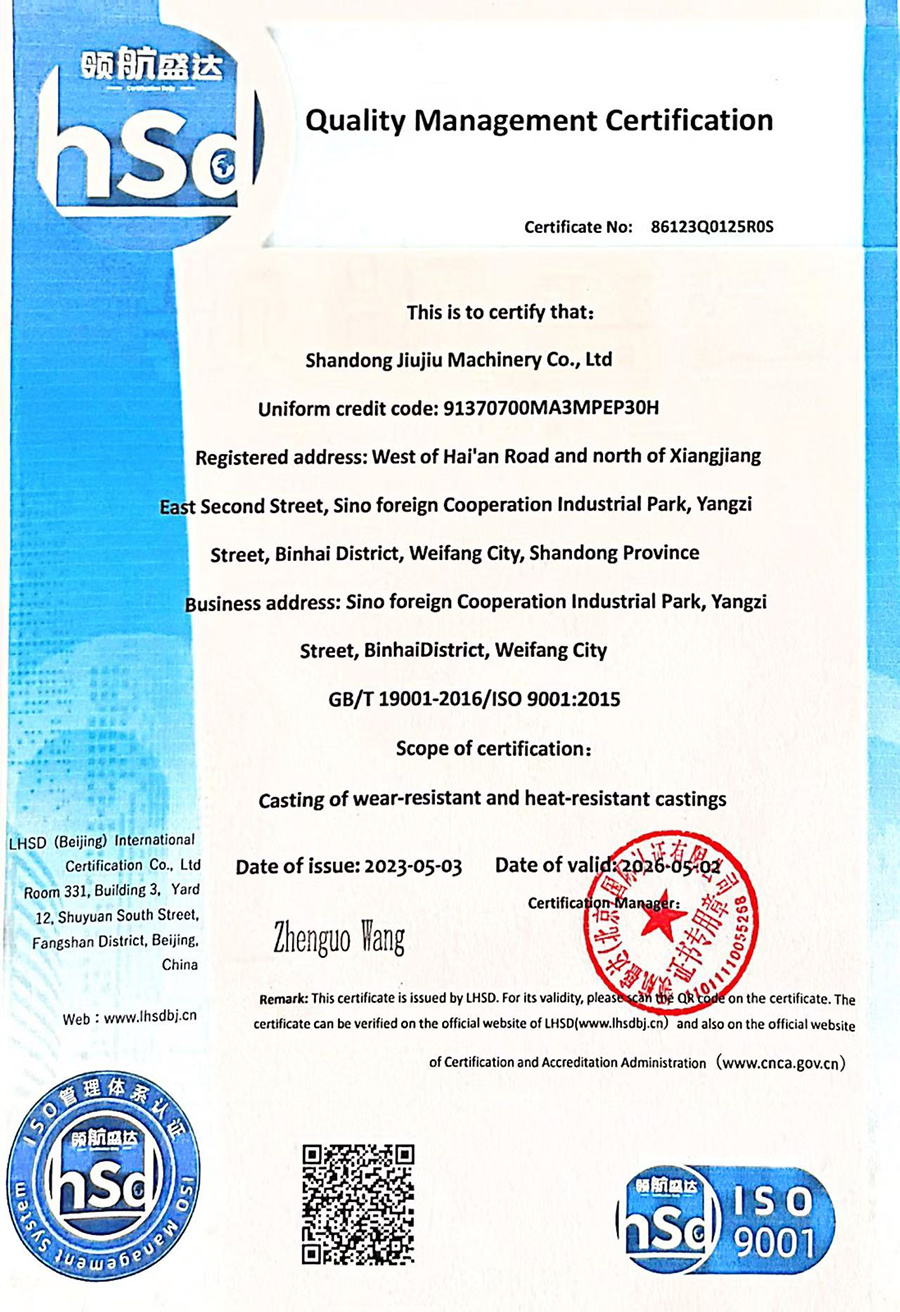

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Grate bars of boilers and furnaces

Grate bars of boilers and furnaces

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products