The distributor plate of the crusher is a key functional component in the crushing equipment. Its design concept and mechanism of action directly affect the working efficiency and overall service life of the equipment. Structurally, the distributor plate is usually installed on the inner wall of the crushing chamber or a specific position. The shape varies according to the type of crusher. For example, it is distributed in a ring in a cone crusher, while it may cover the surface of the movable jaw and the fixed jaw in a jaw crusher. Its core function is to optimize the material flow path, balance the force and wear in different areas of the crushing chamber, and thus improve the stability and uniformity of the crushing process.

The design principle of the distributor plate is derived from an in-depth observation of the movement law of materials. In the crushing operation, the raw materials often show an uneven distribution state after entering the cavity. Some areas have a sudden increase in local pressure due to excessive material accumulation, while other areas may accelerate wear due to lack of buffering. The distributor plate actively guides the material to disperse in a specific direction of the crushing chamber through specially designed guide grooves, protrusions or layered structures on the surface. For example, in the primary crushing stage, the plate may direct large pieces of material to the area with stronger impact force by tilting; in the fine crushing stage, the repeated crushing of fine particles is reduced by diversion, thereby avoiding energy waste.

From the perspective of protecting equipment, the distributor plate essentially plays the role of a "sacrificial layer". Due to the intense friction and impact between the material and the metal parts during the crushing process, if the equipment body directly bears this force, the service life of its core components such as the main shaft and bearings will be greatly shortened. The distributor plate is made of highly wear-resistant materials, which preferentially bears wear and impact, thereby concentrating the loss on replaceable parts. This design not only reduces maintenance costs, but more importantly, it ensures the long-term stability of the equipment power system and transmission structure.

In actual industrial applications, the performance of the distributor plate directly affects the economic benefits of the production line. Taking iron ore crushing as an example, if the diversion effect is not good, it may cause large pieces of ore that are not fully crushed to enter the next level of equipment, causing the screening system to be blocked or the energy consumption of the grinder to increase. In the production of building aggregates, a reasonable diversion design can reduce the generation of flaky particles, thereby improving the quality grade of crushed stone for concrete. In addition, with increasingly stringent environmental protection requirements, the indirect effect of the distributor plate on dust control has also attracted attention - the optimized material flow path can reduce the amount of dust generated by high-speed impact.

The regular inspection and replacement of the distributor plate by maintenance personnel is an important part of ensuring the continuous operation of the crushing system. By monitoring the changing trend of the plate thickness, the overall wear state of the equipment can be predicted, and the crushing parameters can be adjusted or preventive maintenance can be arranged accordingly. In general, as the "invisible commander" of the crushing system, the value of the distributor plate is not only reflected in the physical protection, but also in the optimization support for the overall process flow.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

Quality Inspection Certificate

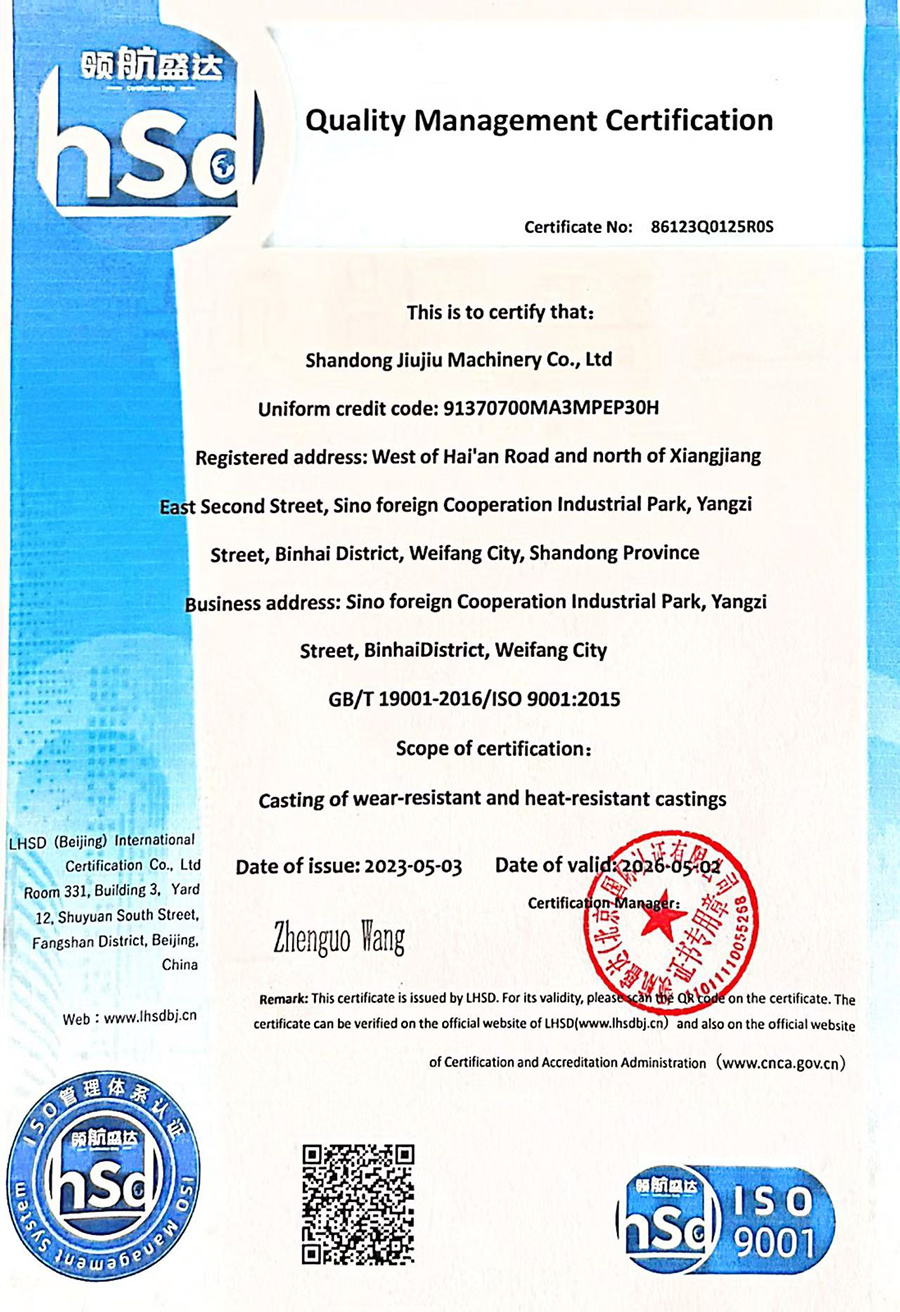

Quality Inspection Certificate 2

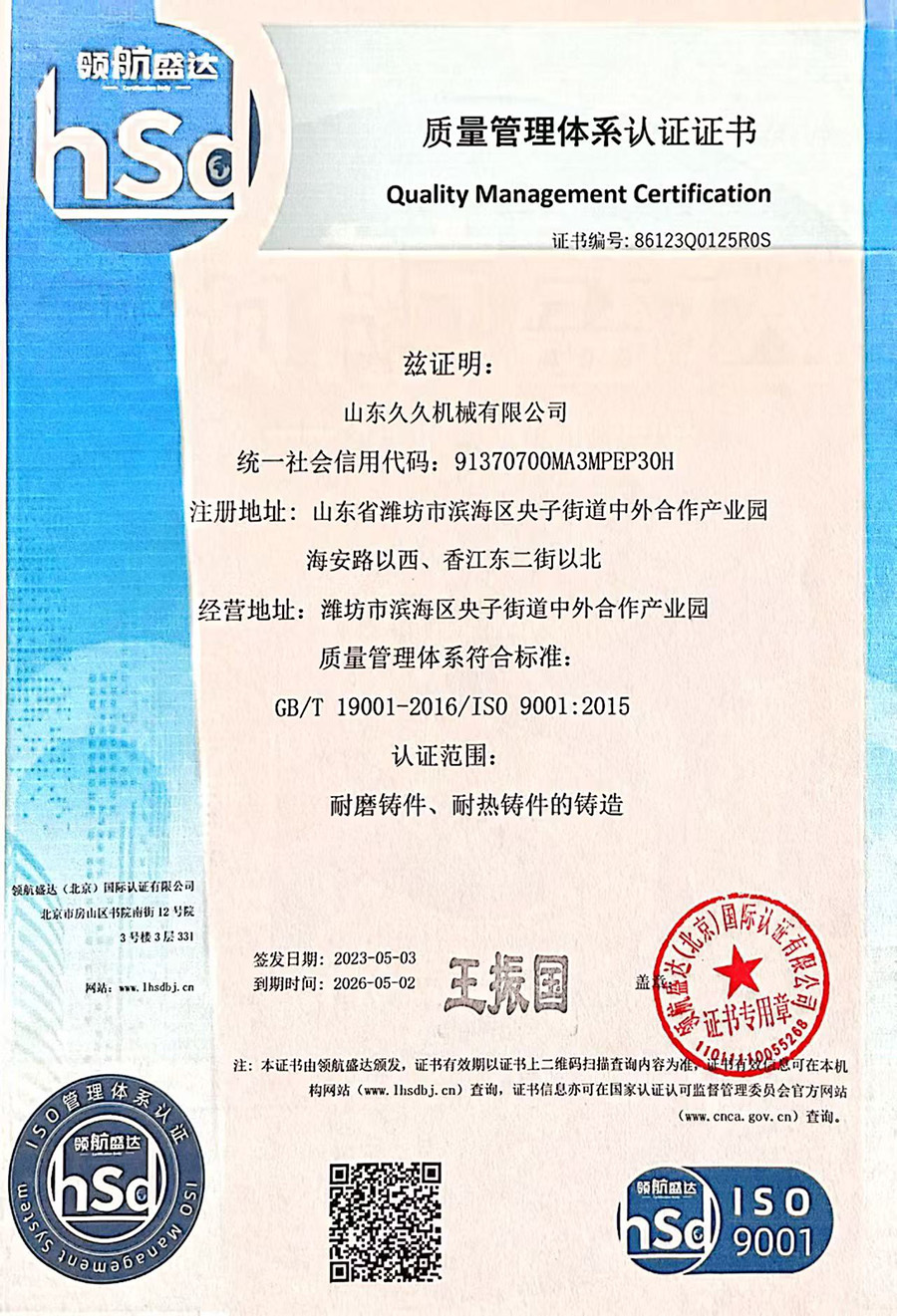

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

crusher distributor plate

crusher distributor plate

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products