Heat resistant steel, as a resistant steel designed for high-temperature environments, has been shining in many industrial fields since its birth with its excellent heat resistance, creep resistance, high-temperature strength and good oxidation resistance.

The reason why heat resistant steel can maintain its unique performance advantages under extremely high temperature conditions is due to its unique alloy composition and fine smelting process. By adding alloy elements such as chromium, nickel, tungsten, molybdenum, and niobium, heat resistant steel can effectively improve the high-temperature resistance of steel, enhance its organizational stability at high temperatures, and prevent grain growth and performance degradation caused by high temperatures. At the same time, these alloy elements can also form a dense oxide protective film, effectively isolating oxygen from direct contact with the steel matrix, thereby slowing down the oxidation rate and extending the service life of the steel.

In terms of application fields, heat resistant steel has shown its wide applicability. From high-temperature equipment such as blast furnaces, converters, and electric furnaces in the metallurgical industry to key components such as cracking furnaces and reactors in the petrochemical industry; from high-temperature components such as boilers and turbine blades in the power industry to applications in extreme environments such as engine hot end components and rocket thrusters in the aerospace field, heat resistant casting has won wide recognition in the market with its outstanding performance.

Especially in the building materials industry such as cement, glass, and ceramics, high heat resistant metal sieve plates, as important screening equipment components, require not only excellent wear resistance, but also good high temperature resistance. These sieve plates can still maintain the accuracy and screening efficiency of the sieve holes in harsh environments of high temperature, high humidity, and high corrosion, ensuring the continuity and stability of the production process.

Heat resistant steel has become one of the indispensable important materials in modern industry with its unique performance advantages and wide application fields.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

Quality Inspection Certificate

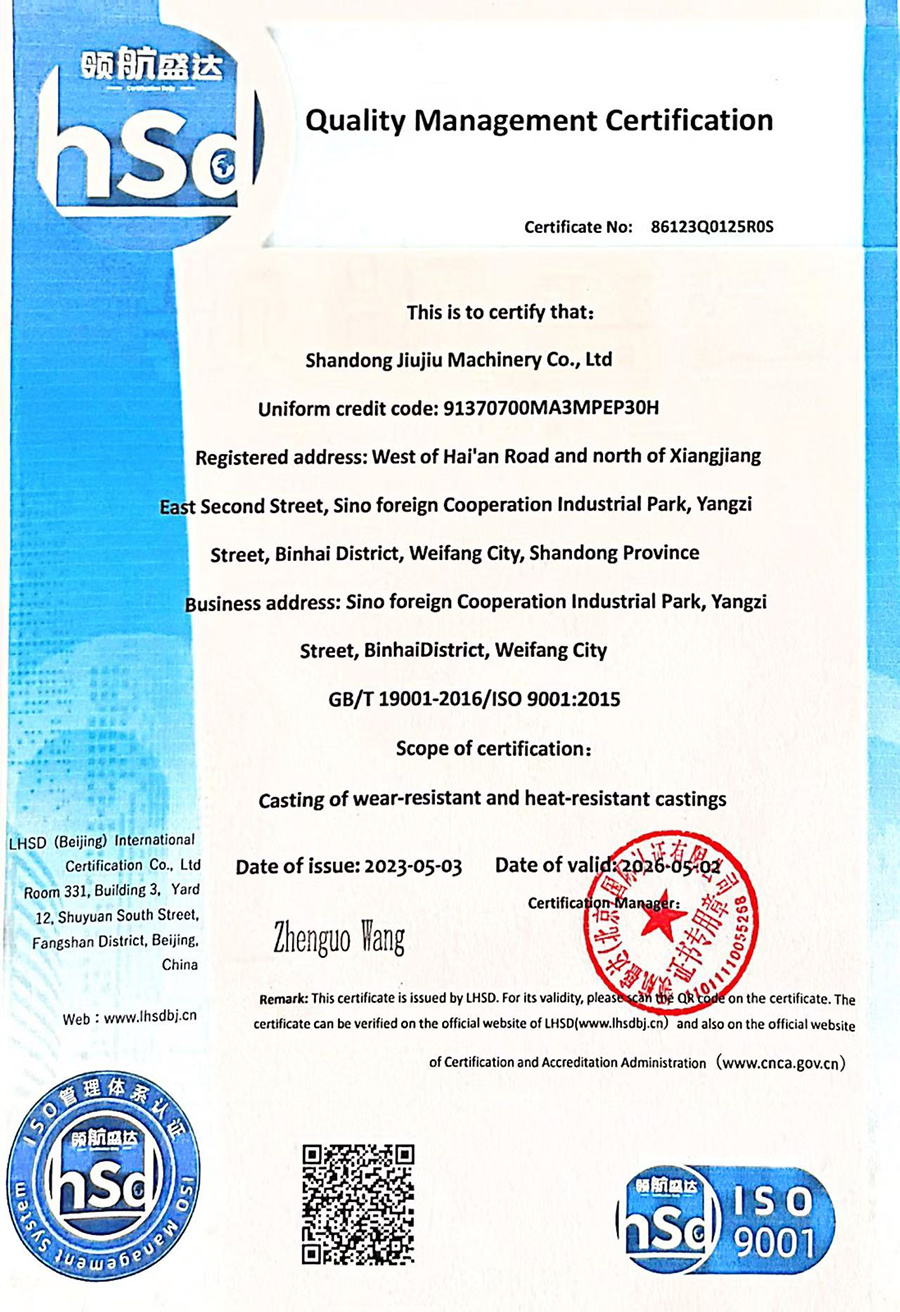

Quality Inspection Certificate 2

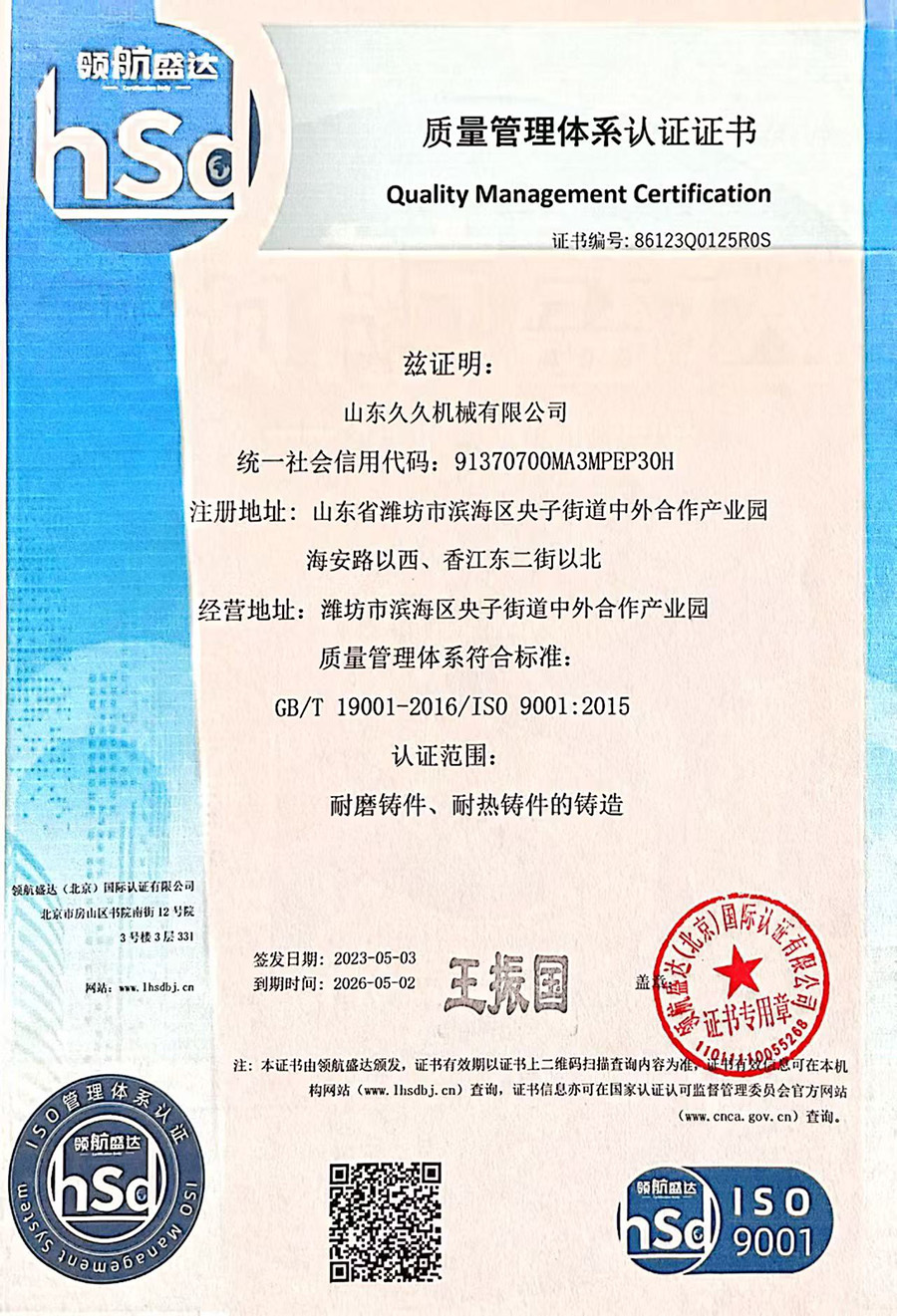

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Heat resistant steel for WTE

Heat resistant steel for WTE

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products