The impact plate in the crusher is one of its core functional components, which undertakes multiple functions such as material crushing, particle size control and equipment protection. In the impact crusher, the impact plate is usually fixed on the top or side wall of the crushing chamber, forming an impact crushing zone with the high-speed rotating rotor. When the material is ejected by the rotor, it hits the surface of the impact plate at a speed of 12-45m/s, and the material is dissociated by converting kinetic energy into crushing force. Its structural design has significant characteristics: the surface is usually wavy or toothed to enhance the impact contact area, the back plate adopts a box-type reinforcement rib structure to improve the bending rigidity, and is connected to the frame by high-strength bolts to form an overall force system. In terms of material selection, the impact plate is mostly cast with high manganese steel (such as Mn13Cr2) or composite alloy steel, and the surface is formed by surfacing tungsten carbide particles to form a 3-5mm wear-resistant layer. The Rockwell hardness can reach HRC58-62, and it can still maintain stable performance when subjected to continuous impacts of 200-500 times/minute. The function of the impact plate depends on the dynamic adjustment system. The distance between the impact plate and the rotor can be adjusted by a hydraulic cylinder or a mechanical screw mechanism (adjustment range 10-50mm), so as to accurately control the particle size of the discharge material (usually adjustable to 3-25mm). For example, in a compound crusher, the backward movement of the impact plate will extend the rebound path of the material, increase the probability of secondary crushing, and improve the uniformity of the product particle size by 15%-20%. For overload protection, the modern impact plate system integrates a pressure sensor. When the pressure in the crushing chamber exceeds the set threshold (such as 35MPa), the hydraulic system automatically moves the impact plate backward to expand the volume of the crushing chamber, and at the same time links the feeder to reduce speed to achieve instantaneous discharge of iron or superhard materials. In a hammer crusher, the impact plate and the hammer head form a coordinated crushing mechanism: the material is first crushed by the impact of the hammer head, and then hits the impact plate to produce a rebound effect. The particles that do not meet the standards are rebounded to the hammering area for cyclic crushing. This design increases the single crushing efficiency to more than 85%. The application scenario of the impact plate determines its differentiated design. In wet crushing conditions (such as clay ore processing), drainage holes with a diameter of 5-8mm are opened on the surface of the impact plate and a polyurethane anti-stick coating is sprayed to prevent the adhesion of water-containing materials. 38. In high-temperature environments (such as metallurgical slag crushing), a double-layer water-cooled structure impact plate is used. A serpentine cooling pipe is set inside, and the working temperature is controlled below 120°C by circulating water. For ultra-hard materials (basalt, quartzite), some models use modular combination impact plates. A stepped alloy liner is set at the front section to bear the main impact, and a screening grid is installed at the rear section to realize crushing-screening integration, reducing the system energy consumption by 10%-12%. Impact plate wear monitoring technology has developed rapidly in recent years. By embedding piezoelectric sensors to detect vibration spectrum changes in real time, combined with AI algorithms, it can predict liner failure 30-50 hours in advance, significantly reducing the risk of unplanned downtime.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

Quality Inspection Certificate

Quality Inspection Certificate 2

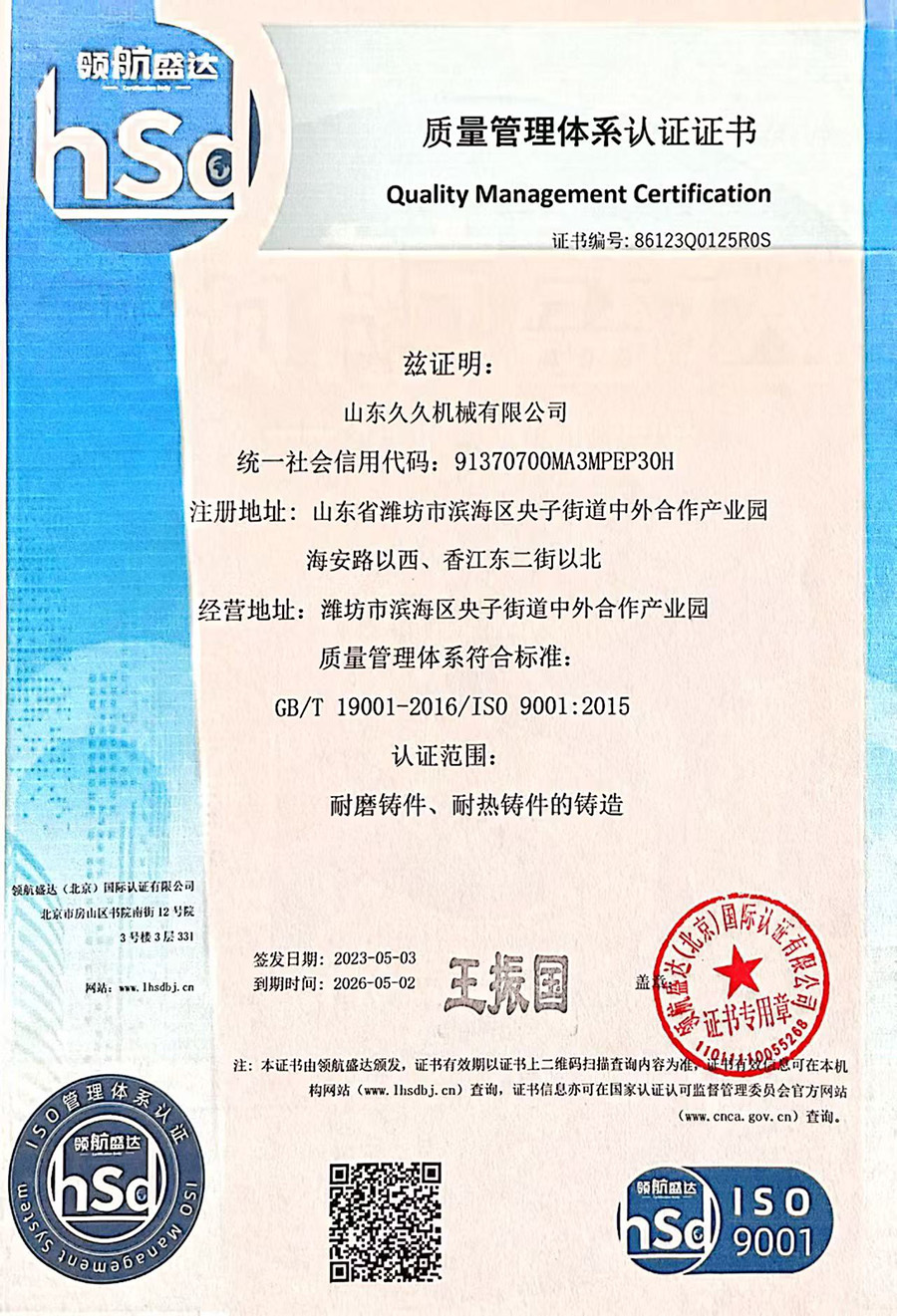

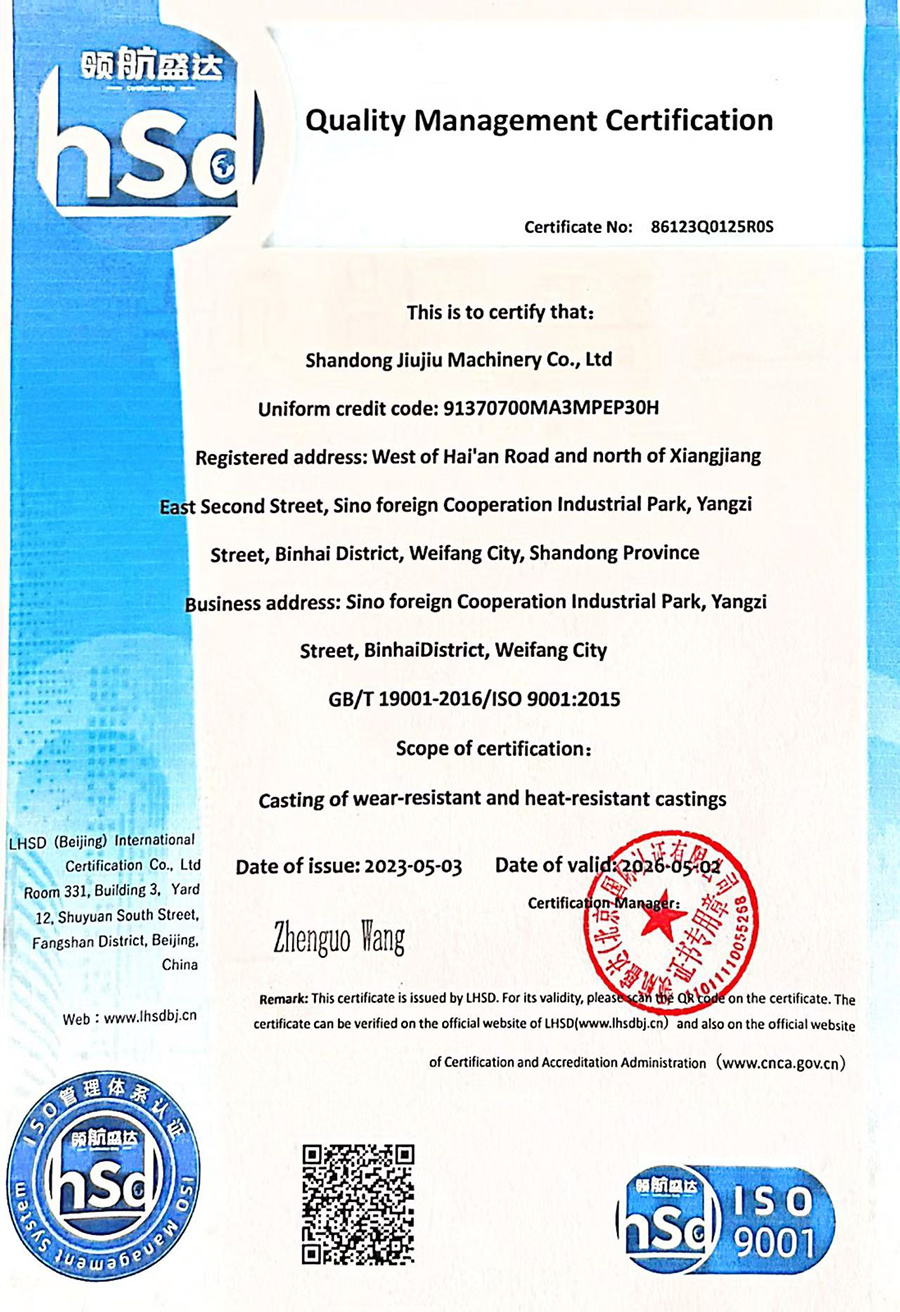

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Impact plate

Impact plate

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products