The lost foam casting process has significant advantages in the manufacture of crusher impact plates. This process directly shapes the foam model, avoiding the complex processes of parting and demolding in traditional casting, and can accurately restore complex curved surface structures. It is particularly suitable for parts with special curvatures or grooves such as impact plates. Since there is no need for draft angle, the size accuracy of the formed impact plate is higher, and the matching degree with the rotor system is better during assembly. At the same time, lost foam casting can make the molten metal fill the cavity more evenly, reduce defects such as pores and slag inclusions, and improve the overall density of the casting, thereby enhancing the impact resistance and wear resistance of the impact plate. In addition, this process reduces the amount of subsequent machining, which not only reduces production costs, but also retains the hardened layer on the surface of the material, further extending the service life. In terms of environmental protection, the waste sand and waste gas generated by the lost foam process are easier to handle, which meets the requirements of modern green manufacturing. Overall, this process achieves an optimal balance of quality, efficiency and cost while ensuring the performance of the impact plate.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

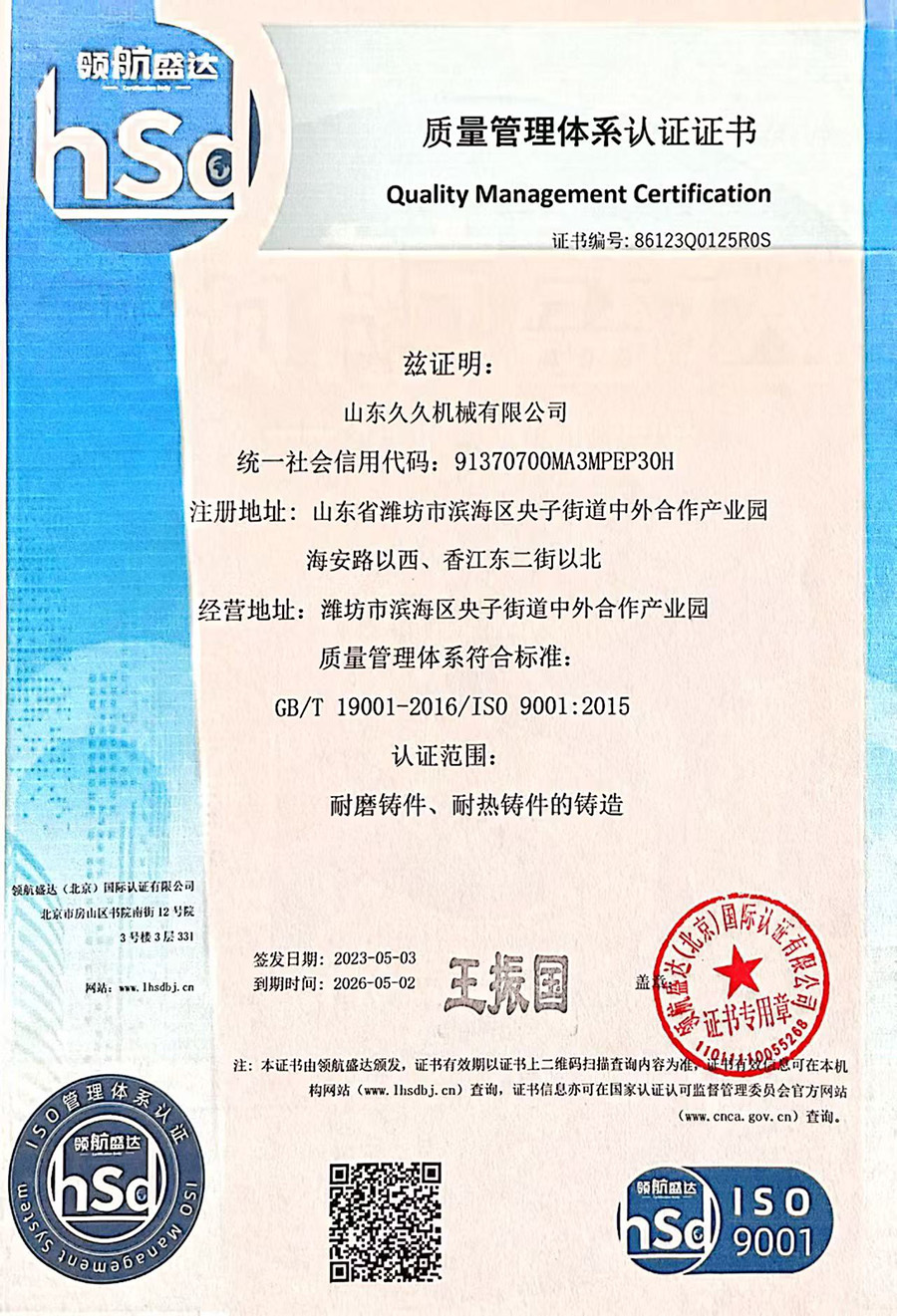

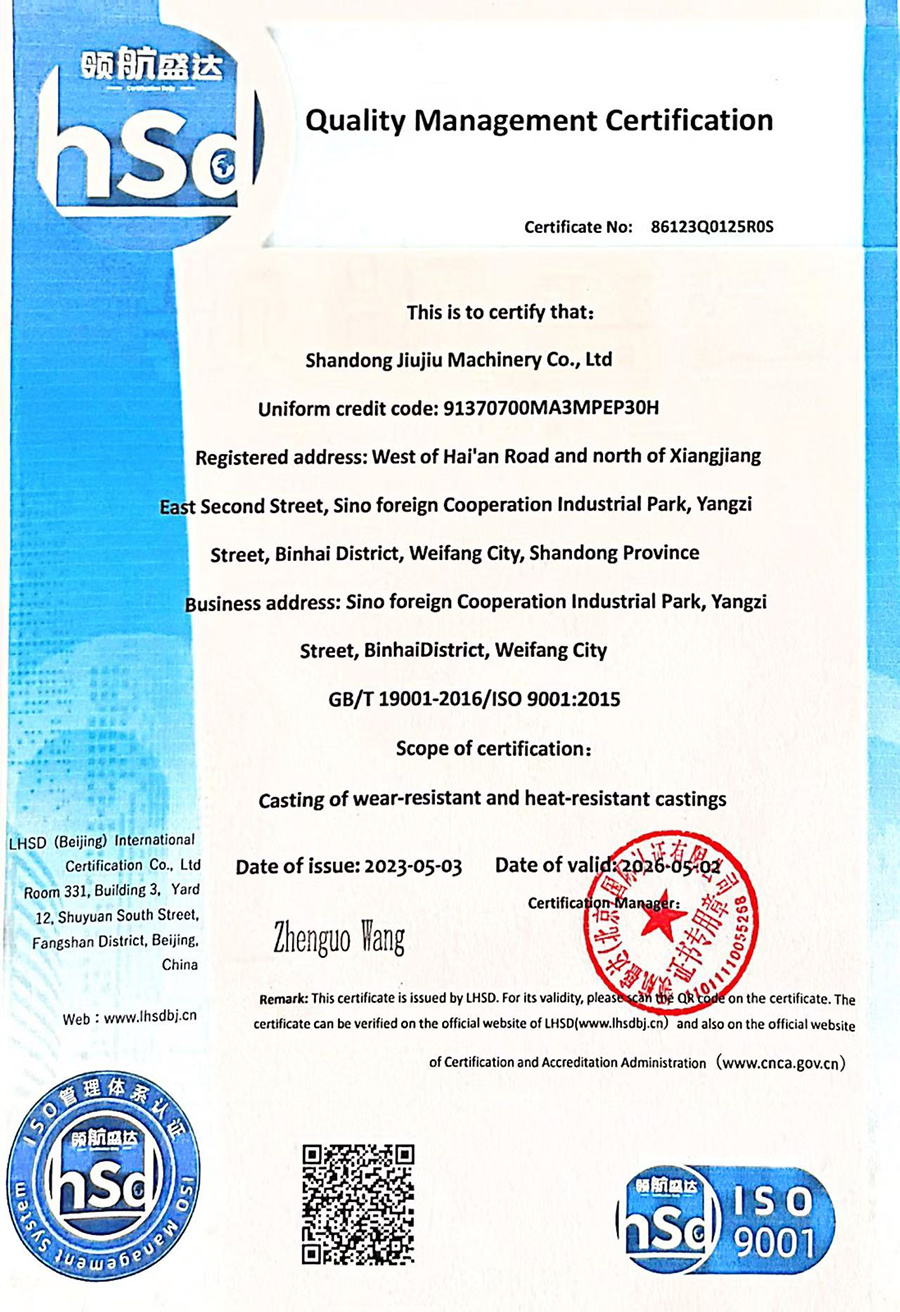

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Mining crusher parts

Mining crusher parts

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products