The selection of coal crusher liner mainly considers wear resistance, impact resistance and economy. Since coal often contains hard impurities such as gangue, the liner needs to withstand continuous friction and impact, so high manganese steel is the most commonly used material. This kind of steel will harden the surface when impacted to form a wear-resistant layer while maintaining internal toughness. For the crushing of lignite with strong corrosion resistance, chromium-molybdenum alloy steel liner will be selected to enhance corrosion resistance. Some crushers with lighter working conditions also use high-chromium cast iron liners, which have better wear resistance but slightly weaker impact resistance. In recent years, composite liners have gradually become popular, such as welding tungsten carbide hard alloy blocks on the matrix, which not only reduces the overall cost but also improves the wear resistance of key parts. Liners are usually designed as modular structures to facilitate partial replacement of severely worn parts. Rubber cushions are also used during installation to reduce vibration noise and absorb part of the impact energy to extend the life of the liner. These designs enable the liner to control the replacement and maintenance costs within a reasonable range while ensuring the crushing efficiency.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

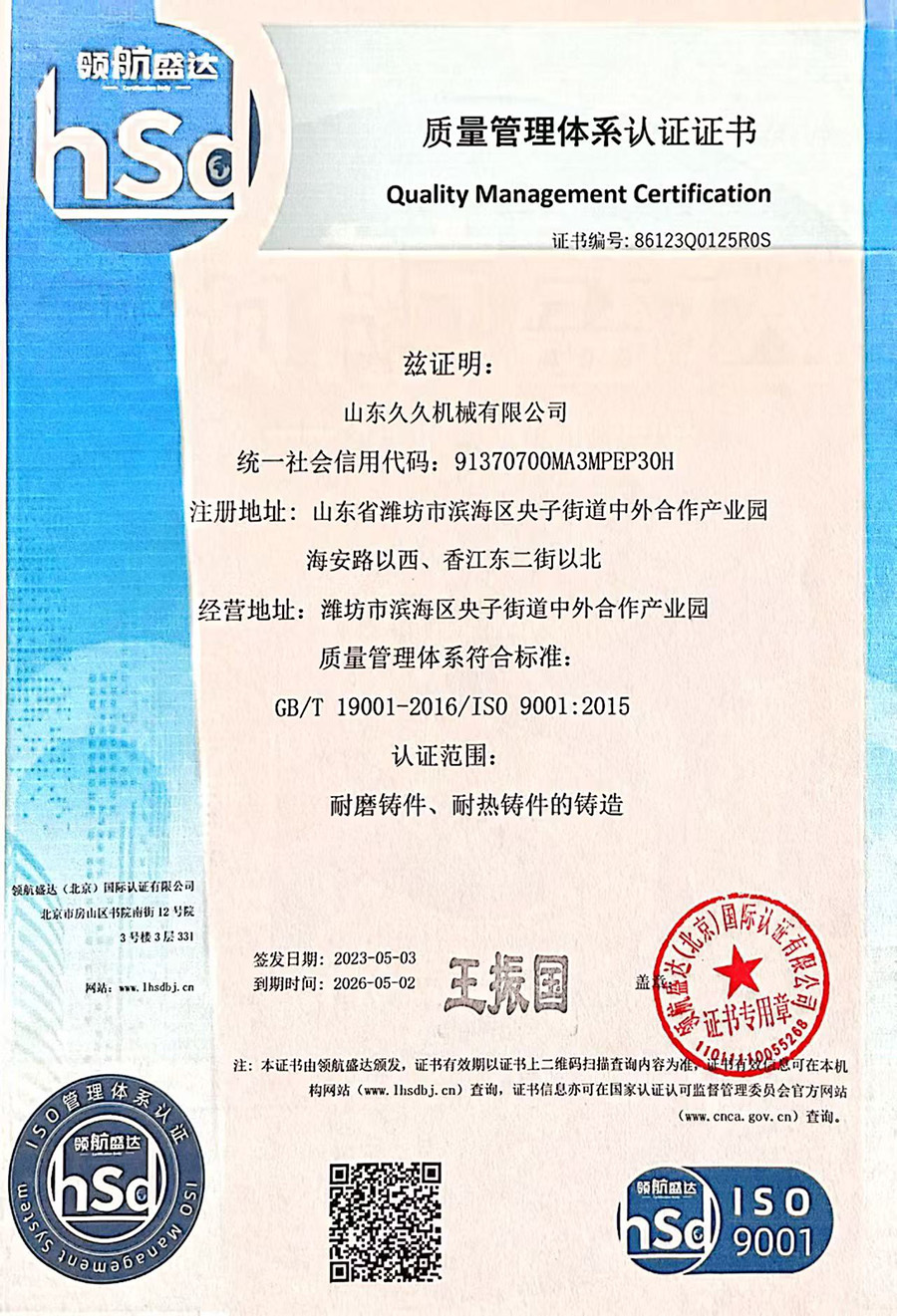

Quality Inspection Certificate

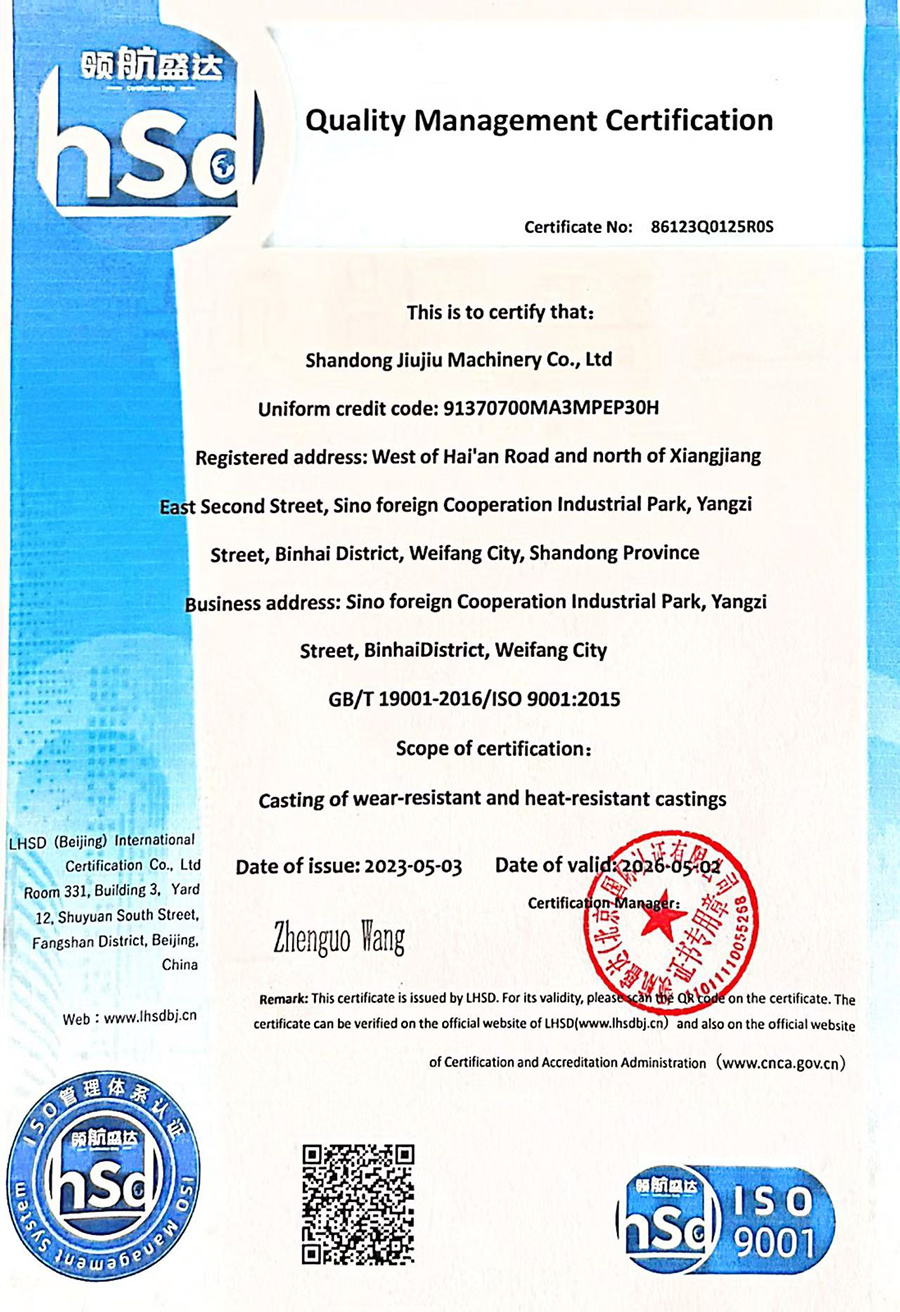

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Coal crusher liner plates

Coal crusher liner plates

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products