The selection of ball mill liner material needs to comprehensively consider factors such as material properties, working conditions and economy. High manganese steel liner (such as Mn13) has excellent impact toughness and is suitable for processing high-hardness ores (such as iron ore and gold ore). It will produce work hardening under impact load, and the surface hardness can reach above HB300; chromium-molybdenum alloy liner has better wear resistance and is suitable for grinding highly corrosive materials. Its service life is 20%-30% longer than that of ordinary high manganese steel. For fine grinding of ceramics, chemical raw materials, etc. to avoid iron pollution, rubber or polyurethane liner can be selected, which has significant noise reduction effect and reduces energy consumption by 10%-15%. High-chromium cast iron liner with drainage grooves is recommended for wet grinding conditions, which can effectively prevent mud adhesion. In recent years, composite liners (such as metal-rubber combination) have gradually become popular, and the wear resistance of the impact zone and the consumption reduction demand of the non-impact zone are taken into account through zoning design. It is recommended to balance the initial cost and replacement frequency according to the actual production capacity requirements. For example, large ball mills with an annual processing capacity of more than 500,000 tons should use high-end alloy liners, while small and medium-sized equipment can consider standardized liners with higher cost performance. Regular monitoring of liner wear (it is recommended to replace it when it is not less than 1/3 of the original thickness) is the key to ensuring grinding efficiency.

Factory

Factory 2

Factory 3

Factory 4

Factory

Delivery site

Delivery site 2

Delivery site 3

Delivery site 4

Delivery site

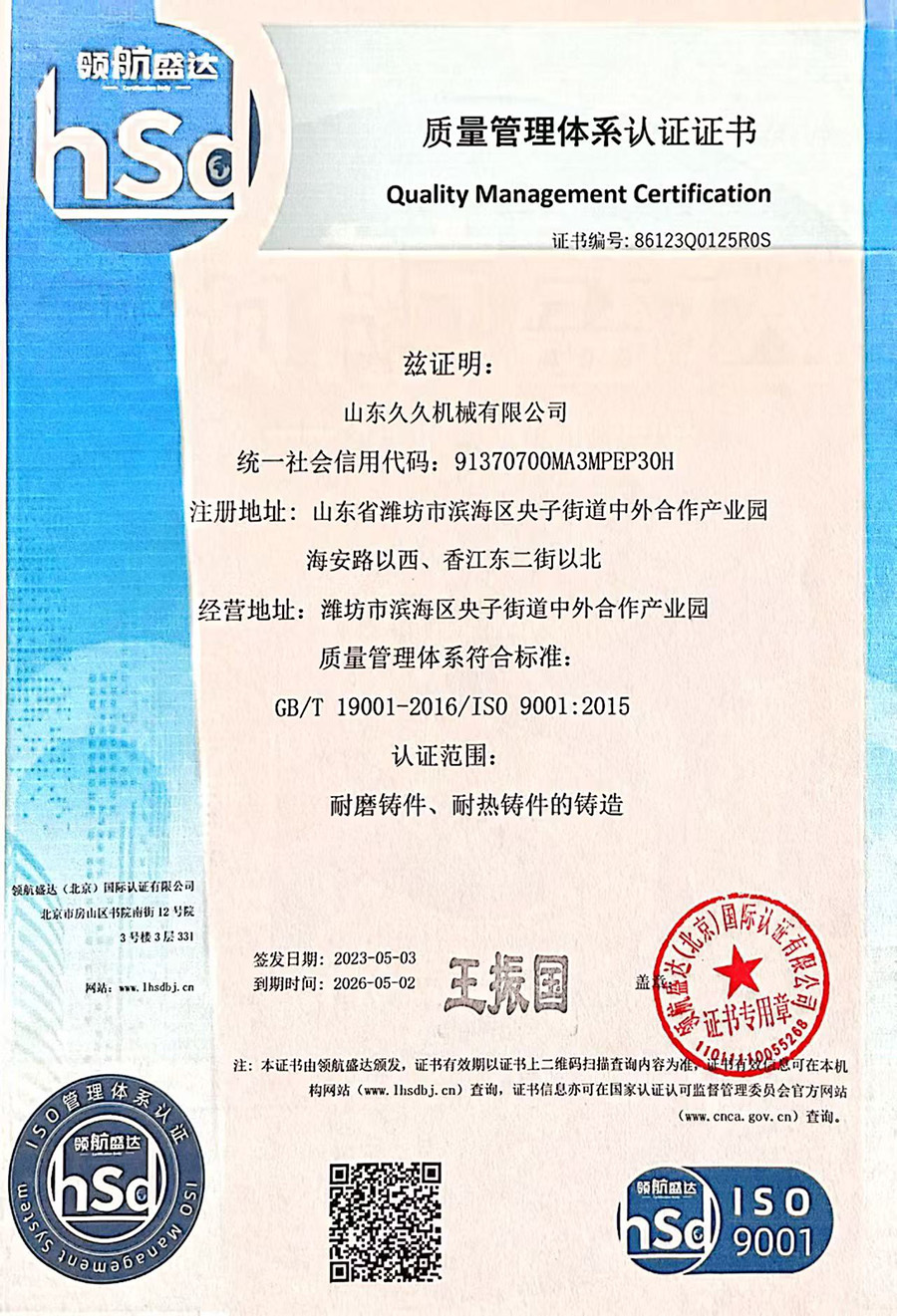

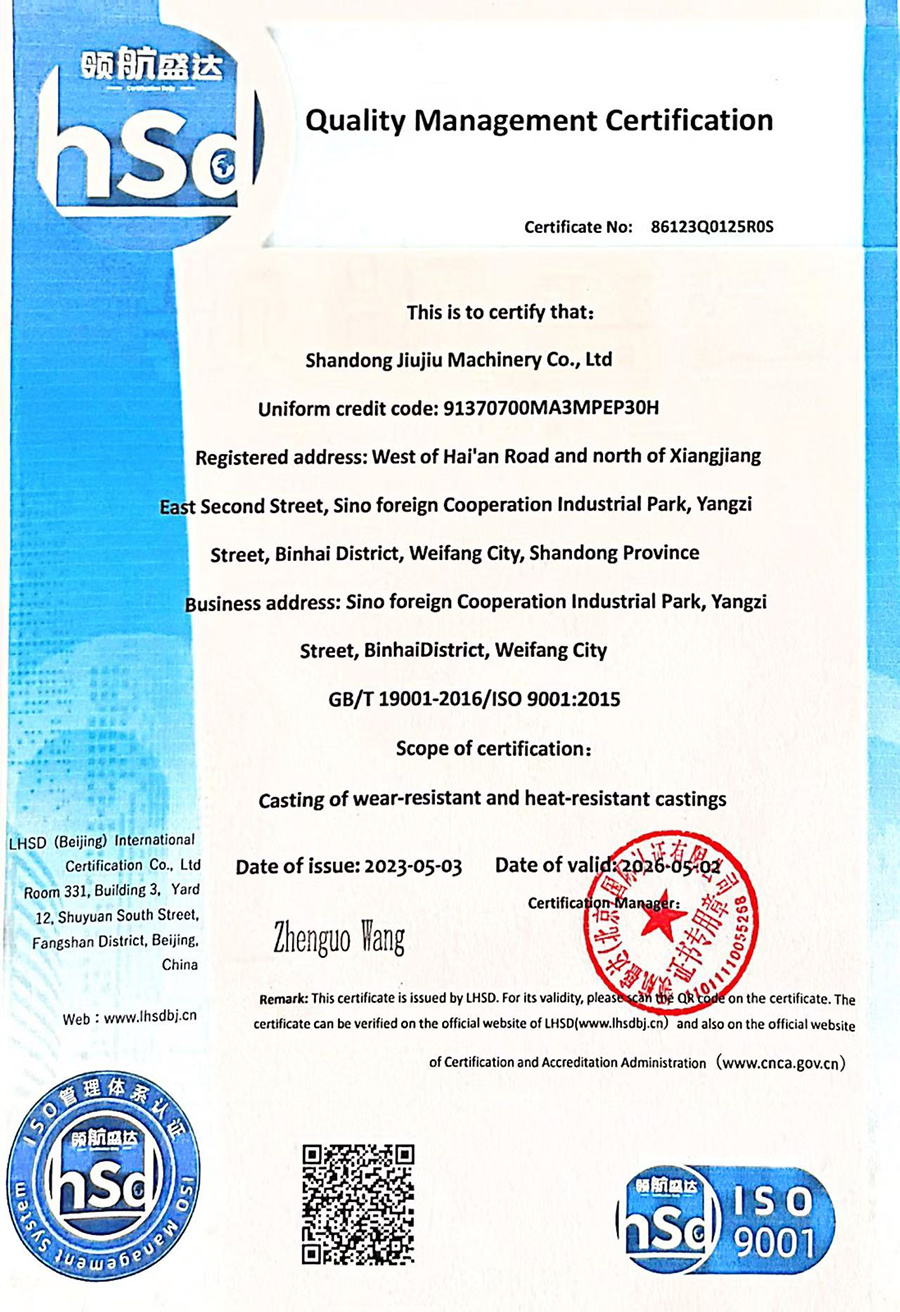

Quality Inspection Certificate

Quality Inspection Certificate 2

Quality Inspection Certificate

Customer visits

Customer visits 4

Customer visits 3

Customer visits 2

Customer visits

Application

Application 2

Application 3

Application 4

Application

Keywords

Ball mill liners

Ball mill liners

Contact Us

Telephone:+86-15615567719

Weifang Binhai New Area Sino-foreign Cooperation Industrial Park, about 260 meters west of the intersection of Hai 'an Road and Zhenhai Street

Related Products

We believe: you will like more of our products