Our service

Pre-sales

After receiving the drawings or samples provided by customers, we will use strict manual measurements and advanced equipment to measure, and can process and produce 100% in accordance with customer requirements to provide customers with satisfactory products.

On sale

After receiving the drawings or samples provided by customers, we will use strict manual measurements and advanced equipment to measure, and can process and produce 100% in accordance with customer requirements to provide customers with satisfactory products.

After Sales

After receiving the drawings or samples provided by customers, we will use strict manual measurements and advanced equipment to measure, and can process and produce 100% in accordance with customer requirements to provide customers with satisfactory products.

Our Hot Products

Heat-resistant steel is an alloy engineered for high-temperature environments (usually above 500°C), with properties of oxidation resistance, corrosion resistance, and creep resistance, finding wide use across industries.

The distributor plate of the crusher is a key functional component in crushing equipment. Through the specially designed guide grooves, protrusions or layered structures on its surface, the distributor plate actively guides materials to disperse in a specific direction within the crushing chamber.

Manganese crusher liner is mainly used in quarrying, mining, excavation, coal industry and other fields, and bears huge crushing force and material friction.

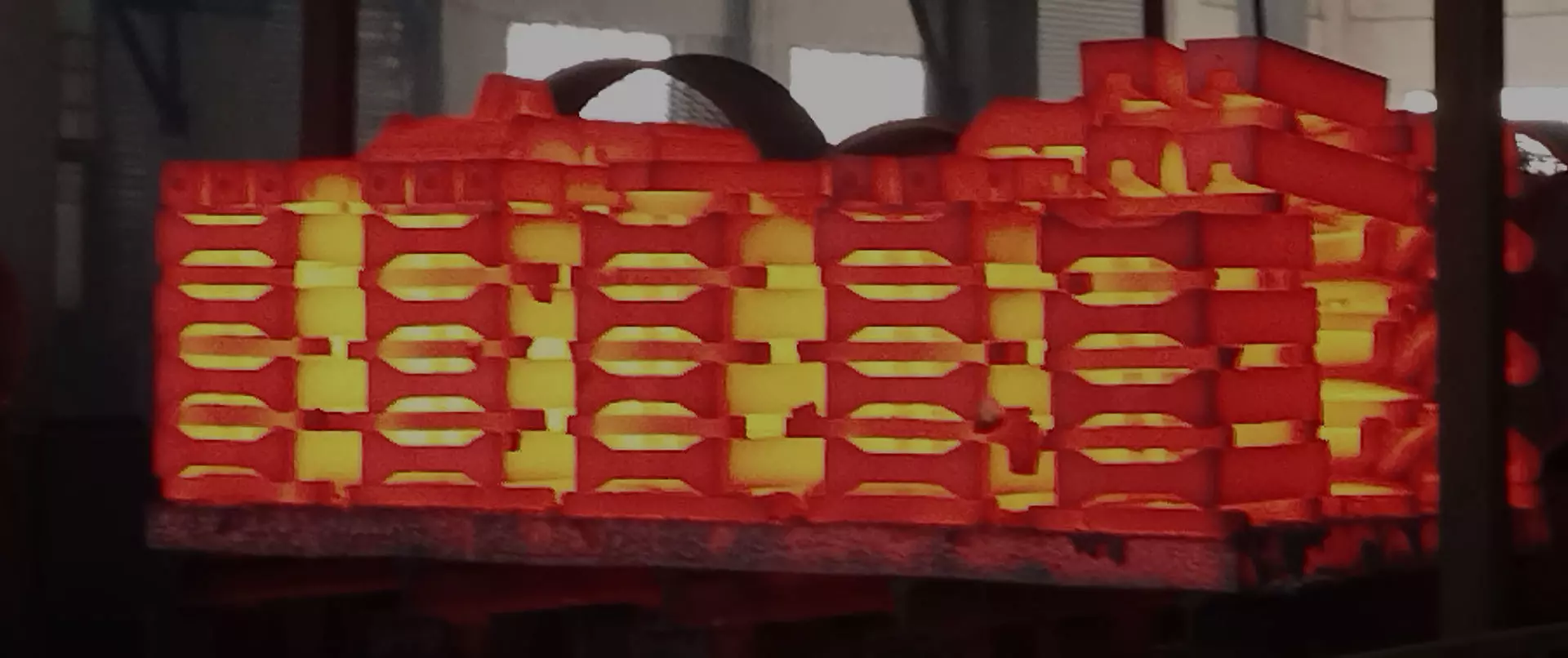

Waste Incineration Grate Bars are key parts forming mechanical incinerator beds, directly contacting municipal waste through drying, ignition, combustion, and ash burnout. They move to mix/advance waste and enable even air flow for full combustion.

impact plates for impact crusher

The impact crusher features three core plate components—blow bars (hammers), impact plates, and side plates—with impact plates being pivotal to refining crushing results.

As a key component in crushing equipment, the manganese hammer for crusher plays an important role in many industrial fields with its excellent physical properties and durability.

Waste incinerator grate bars are crucial components of a waste-to-energy plant's furnace, designed to support, move, and promote the complete combustion of waste materials. As a key structure for garbage transportation and combustion in the incinerator, the furnace grate system needs high strength, heat resistance, and corrosion resistance.

China high chrome abrasion resistant blow bars

The crusher blow bar is the core working part of the crushing equipment, especially in the vsi crusher, impact crusher and other equipment.

Service first

Advagtage

A professional wear-resistant and heat-resistant casting factory, focusing on the production of grate bars, shredder hammers, plate hammers, tooth plates, impact plates, wear-resistant linings and other products.

Manufacturing Experience

Nearly 10 years of experience in the production of wear-resistant castings and heat-resistant castings.

Advanced Equipment

The entire production line is semi-automatic and fully automatic, which more accurately guarantees the quality of each product.

Wide Range 0f Partners

The products are mainly exported to overseas markets such as Japan and Europe.

Product Quality Assurance

Quality products and quality service is our responsibility to customize exclusive products for you.

FAQs

FAQ

We provide free calling services to solve your problems.

What operating environments can your castings withstand?

Our castings are primarily designed for high-temperature, high-pressure, and corrosive environments. Made from high-performance alloys, our products remain stable even under extreme conditions and are widely used in industries such as mining, metallurgy, and chemicals.

What is the maximum operating temperature for heat-resistant castings?

700°C-1200°C, depending on the chemical formula.

What is your lead time for samples and orders?

Samples: 30-40 days after mold completion. Orders: 35-50 days, depending on order complexity and material requirements. For custom products, delivery times are determined based on actual conditions.

Why choose us?

① We have extensive export experience.

② As a foundry, our prices are more competitive than those of trading companies.

③ We have a complete production system, including a technical team and inspection department.

④ We maintain strict quality control over production processes and tolerances.

⑤We keep all drawings and business information strictly confidential.

How to test your quality products?

Upon delivery, we will provide customers with a material inspection report and dimensional inspection data to verify product quality. We also offer a practical suggestion for interested customers: you can sample and test two sets of products. All good business relationships begin with testing and mutual trust. This approach helps customers intuitively verify product quality.

Online messages

Are you looking for a variety of products and solutions?

We are committed to providing you with quality products and services. If you have any questions or need more information, please feel free to contact us